Six-year-old Joey Toce loves being outdoors. But just moving around the yard can be difficult for the cheerful Southington boy who has cerebral palsy.

With the help of students from the School of Engineering, Joey recently expanded his mobility with a sleek new all-terrain “Joe-kart” – similar to a go kart – that can be operated remotely by his parents or by Joey himself once he learns how to manipulate the switches.

The students also made a “modified slide coaster” for Joey that will allow him to enjoy the thrill of rushing down a roller coaster-like slide time and again without fear of being injured. Joey’s mother, Katrina Toce, said Joey loved a commercial version of the slide but often had difficulty controlling his posture and legs during the descent. It also was hard for her to pull Joey back up to the top of the device for another run. The UConn-made slide has a special harness for Joey’s safety, and a motorized winch to help re-set the device for repeated use. During the past year, the students also made Joey an adaptive sled; a Hungry, Hungry Hippos game; and a wireless device for playing DVDs and CDs.

“All of these have been wonderful for Joey. He really enjoys the independence they allow him,” says his mom. “Joey loves speed and all things that ‘go,’ and he enjoyed being pulled around the yard by his dad in the snow. … All of the projects far exceeded our expectations and all three design teams did a wonderful job!”

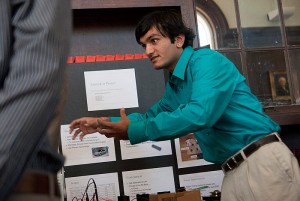

The senior engineering teams that worked on Joey’s projects showcased their devices and presented them to Joey and his family during the School of Engineering’s annual Senior Design Presentation Day on April 30.

Professor John Enderle, director of the University’s undergraduate biomedical engineering program, has been helping his students design and build adaptive devices for disabled children and adults since 1988. The program allows students to use the problem-solving, creative and technical skills they learned at UConn to tackle real-life situations. The projects are funded by the National Science Foundation and materials are provided through corporate donations.

“It’s a very eye-opening experience for them at first,” Enderle says of his students. “The level of challenges we place on them is unlike any other course they have taken before. But by the end of the second semester, they think this is the best course they have ever taken. The skills they learn and their experiences interacting with their teammates and the families are second to none.”

The biomedical engineering students also helped 10-year-old Annalee Hughes of Tolland, who also has cerebral palsy, by developing a physical therapy device that will enable her to strengthen her leg muscles and gait over time. The device allows Annalee to “walk” while braced and harnessed in a sturdy, full-size walking apparatus. Another team built a low center of gravity motorized chair for Annalee that will allow her to safely maneuver around her yard without tipping over.

The biomedical teams were only part of the Design Day showcase at Wilbur Cross. On another side of the building, close to four dozen teams of mechanical and electrical engineers showcased their individual projects, which ranged from a solar-powered portable cooler for use at the beach to an improved electric car propulsion system that relies on advanced alternators to replace more traditional AC motors. More than 70 industry- or government-sponsored projects were displayed. Separate design demonstrations for chemical, civil, computer, and environmental engineering took place earlier in the week. Awards for top designs ranged from $500 to $1,500.

Thomas Barber, a professor-in-residence of mechanical engineering, said his students tackle real-world projects posed by Connecticut industry and business leaders. Many seniors are offered jobs based on the success of their designs, and a number of devices have patents pending. For instance, Barber said, a device students created that uses a pneumatic actuator and high-impact water column to test the strength of composite laminates has important implications for the submarine industry and is likely to be put into use soon by the Electric Boat division of General Dynamics in Groton, the project’s sponsor. He said another device developed by students last year is going to be part of the Wiremold Co.’s product line this year. Wiremold is a major manufacturer of wire products and devices located in West Hartford.

“The confidence the students exude is always refreshing. This is really an excellent show,” says Stephen Parkinson, whose Capewell Components Co. sponsored a team that used Newtonian kinematics and elaborate engineering equations to create a computerized model that will help packages dropped from airplanes arrive at their proper destinations. Located in South Windsor, Capewell is the world leader in aerial drop systems.

For senior electrical engineer Sean Tierney, working on his team’s solar-powered cooler was a memory that will last a life time. But the best is yet to come. Tierney, whose team built a small plastic cooler outfitted with thermoelectric modules to replace traditional ice, is going to work as an engineer for United Technologies after he graduates.