Smog, pollution, climate change. It’s impossible to turn on the news without hearing about the environmental threats faced by modern society.

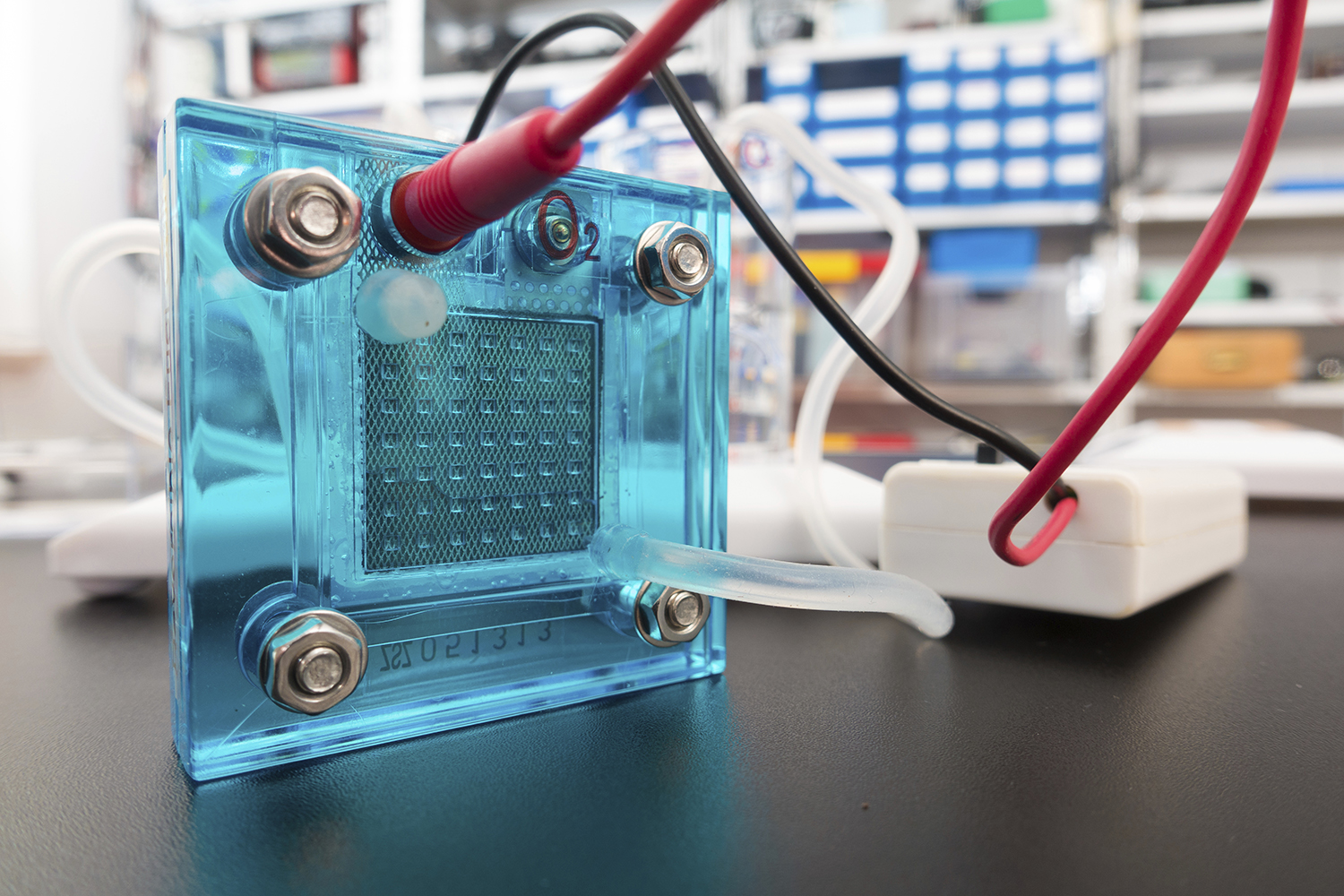

Many believe that hydrogen fuel cells and electrolyzers could be the key to creating sustainable energy in the future. Despite significant investments in these promising technologies, cost and durability are still problematic. This is due to expensive catalysts and low volumes of manufacturing for the electrolyzers and fuel cells components.

UConn assistant professor of materials science and engineering, Jasna Jankovic and Svitlana Pylypenko, assistant professor of chemistry from the Colorado School of Mines (Mines) are teaming with industrial partners Pajarito Powder and Forge Nano, the U.S Department of Energy’s National Renewable Energy Laboratory (NREL), and Fraunhofer Institute for Solar Energy Systems in Germany (ISE) to accelerate the development of high volume fabrication of components to facilitate the development of sustainable and zero-emission energy generation technologies.

The team will compare the impact of various processes for scale-up of electrolyzer and fuel cell electrodes on electrode morphology and performance, based on innovative and state-of-the-art catalysts. With the Partnership for Innovations grant from the National Science Foundation, Jankovic and Pylypenko will provide a common platform for advanced and sophisticated characterization for the developed products and establish process-properties-performance correlations. This will make it possible for other industrial partners to develop the tools and replicate this process, which will further increase commercialization of this technology.

The main barrier to the widespread adoption of polymer electrolyte fuel cells for the automotive application and electrolyzers for hydrogen production is the cost of the fuel cell or electrolyzer stack. There is also a lack of knowledge surrounding the performance of electrodes made with catalysts that have novel morphologies and chemistries.

The team plans to deliver 25 gram batches of novel catalyst produced at scale by Pajarito Powder, an industrial partner in this project, to insure viability of electrode fabrication. Forge Nano, another industrial partner, will enhance durability using their atomic layer deposition approach. NREL and Fraunhofer ISE, funded via state and national government resources, will produce the electrodes using a range of methods and perform in situ testing of the electrodes to elucidate performance. Correlations between catalyst composition and morphology, structure and ink processing parameters and properties, electrode structure and membrane electrode assembly performance will be identified for a set of commercially available catalysts, as well as novel catalysts produced under this project by industrial partners. This will provide feedback to current and other potential industrial partners that synthesize catalyst for use in innovative new technologies.

Due to the collaborative nature of this project, students will have extensive technical, leadership, organizational, communication, and entrepreneurial training. This will help to prepare the students as future leaders in the clean energy sector. International workshops on advanced manufacturing and characterization of fuel cells and electrolyzers will help to expand interactions with partners and form larger networks. The first workshop, organized by Jankovic and held in September 2019 at UConn, will continue annually, alternating between UConn and Mines/NREL.

In addition to future workforce development, the results of this project will be beneficial to the clean energy sector by promoting the transition from low-scale, costly electrode fabrications to large-scale, economically viable approaches. Economically, the increased durability, along with decreased platinum group metal content will result in reducing both the total capital costs and mitigating dependence on commodity metals.

The availability of fuel cells and electrolyzers will have positive ecological impacts and allow for energy and economic independence. This will lead to an expansion of economic opportunities through new sources of clean energy used in all economic sectors. Protocols and findings from the common characterization platform will be disseminated to the community to further promote and facilitate the deployment of future innovations.

Svitlana Pylypenko is an assistant professor in the Chemistry Department at the Colorado School of Mines. She is also involved in the interdisciplinary Materials Science Program at Mines and holds a joint appointment at NREL. She received her PhD in chemistry from the University of New Mexico. Pylypenko’s group investigates research interests place emphasis on the surfaces and interfaces of applied materials towards development of cost-effective materials for alternative energy applications. Emphasis is placed on multi-technique, multiscale analysis, and in-situ and in-operando studies bridging surface analysis, surface science, and catalysis.

Jasna Jankovic is an assistant professor in the Department of Materials Science and Engineering, a member of the Center for Clean Energy Engineering (C2E2), and an affiliate of the Institute of Materials Science at the University of Connecticut. She received her PhD from the University of British Columbia. Jankovic’s research interests lie in the development and application of advanced imaging and spectroscopy techniques, 3D material design and imaging, fuel cells, advanced nanomaterials for clean energy, electrospinning for clean energy applications and templating nature designs for applications in clean energy.

Grant Number: NSF 1800585