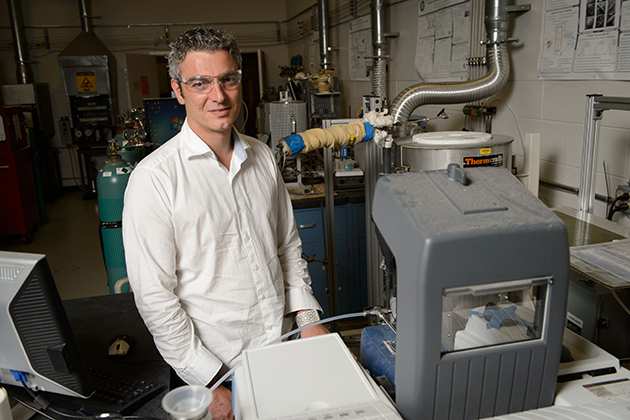

George Bollas, an assistant professor in the Department of Chemical & Biomolecular Engineering, is the recipient of a prestigious American Chemical Society Petroleum Research Fund Doctoral New Investigator Award.

The awards support innovative research in the petroleum field and promote the development of promising engineers and scientists. The award program provides career opportunities to young faculty and their undergraduate and graduate students by supporting advanced scientific research.

The goals of the American Chemical Society Petroleum Research Fund are to support fundamental research in the petroleum field, and develop the next generation of engineers and scientists through the support of advanced scientific education.

Bollas’ research project will explore aspects of Fischer-Tropsch Synthesis selectivity. The Fischer-Tropsch process is a collection of chemical reactions that provide a means of producing transportation fuels from carbon monoxide and hydrogen, a combination referred to as synthesis gas. This reaction also produces excess hydrocarbon products in addition to materials for fuel, so there remains a need to make this process more selective.

The equipment Bollas is using in his research includes a conical spouted bed reactor for biomass fast catalytic pyrolysis and chemical-looping combustion of coal or biomass. The development of this reactor was supported in part by the UConn Intermediate Research Equipment Award.

Through Bollas’ research, it may be possible to significantly improve the selectivity of this process to make the synthesis of fuel through Fischer-Tropsch more efficient and economical. Bollas and his research group plan to examine novel catalyst synthesis methods that enhance the selectivity of FTS toward intermediate-chain length hydrocarbons, particularly synthetic gasoline.

The benefits of making Fischer-Tropsch a more efficient and less centralized process are energy independence and security. In addition, the vast unexploited resources of natural gas found recently in the U.S. make natural gas a major source for energy and fuels production. Bollas’ new experimental work will provide the capability to expand research exploring alternative fuels and efficient processes within the Chemical & Biomolecular Engineering Department and in the Center for Clean Energy Engineering.

Bollas is a process design expert, and recipient of an NSF CAREER Award in addition to the ACS award. His research focuses on biomass pyrolysis, coal and biomass to liquids, Fischer-Tropsch synthesis, chemical-looping combustion, and waste to energy processes.