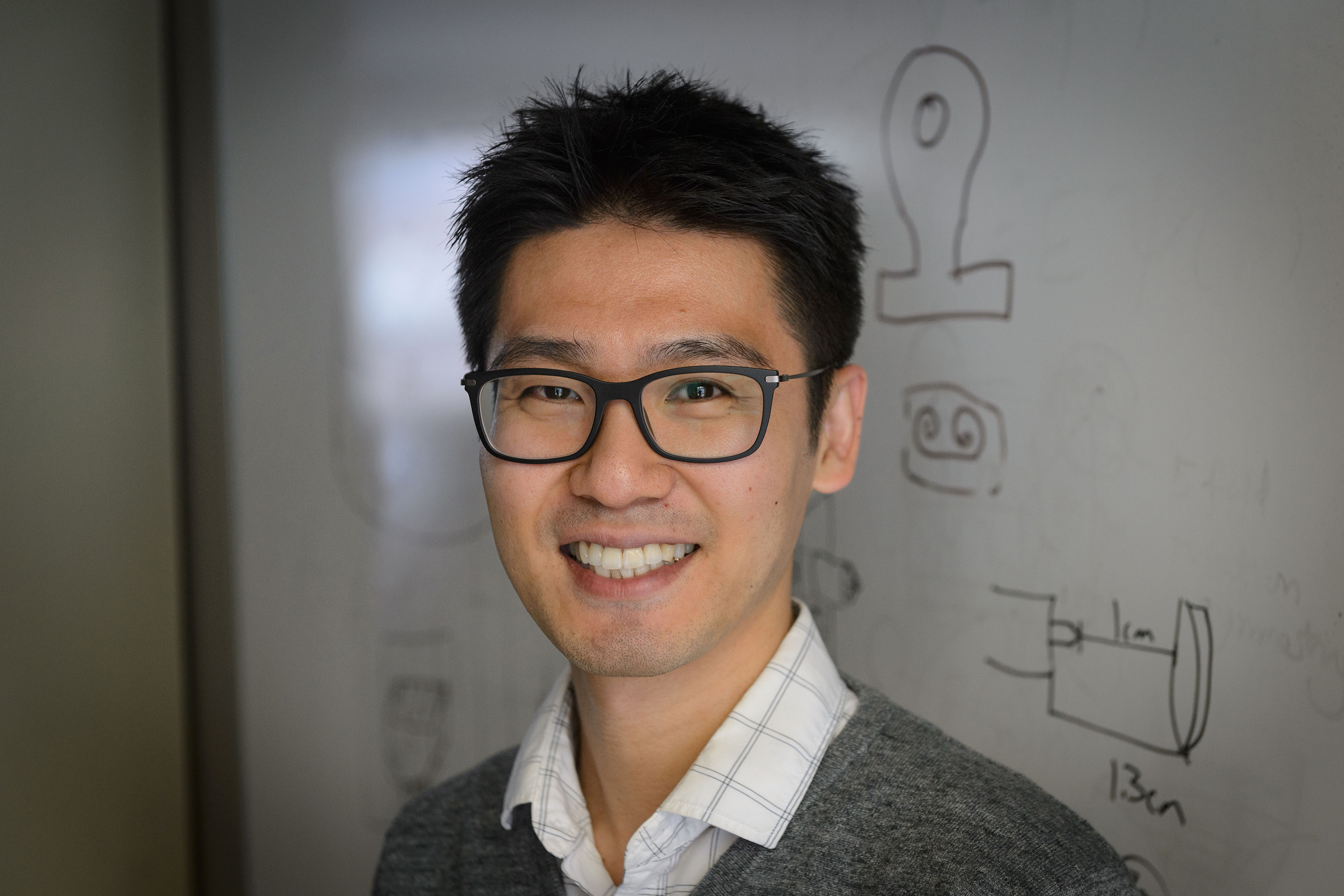

UConn materials science and engineering researcher Seok-Woo Lee and his colleagues have discovered super-elastic shape-memory properties in a material that could be applied for use as an actuator in the harshest of conditions, such as outer space, and might be the first in a whole new class of shape-memory materials.

If you have ever had braces or wear eyeglasses, you may have already come in contact with shape-memory materials. With applications in a wide range of consumer products such as “unbreakable” frames for glasses, and civil industrial structures like bridges, materials with shape-memory properties can return to their original shape by magnetic forces or heat even after being significantly deformed.

Our results can be applied to more than 400 similar materials. This discovery opens up an entirely new area of research on superelastic materials. — Seok-Woo Lee

Lee, who is Pratt & Whitney assistant professor of materials science and engineering, studied calcium iron arsenide, or CaFe2As2, which is an intermetallic better known for its novel superconducting properties. Since the material is commonly used in high-temperature superconductors, extensive research had already examined the compound’s superconducting and magnetic properties. Inspired by previous research conducted at the U.S Department of Energy’s Ames Laboratory by Paul Canfield on calcium iron arsenide’s electronic properties, Lee set out to measure the material’s high degree of pressure and strain sensitivity for potential applications as a structural material.

Working with a team of graduate and undergraduate students at UConn and collaborators at Ames Laboratory, Drexel University, and Colorado State University, Lee discovered that not only did CaFe2As2 exhibit the ability to “bounce” back into its original shape, it showed “giant super-elasticity.” While normal metal alloys or intermetallics recover 0.5 percent of the pre-deformation shape once the compressing force has been removed, CaFe2As2 recovers more than 13 percent.

This video demonstrates the intermetallic compound’s super-elasticity during a cyclic micro-compression test conducted by John Sypek, a UConn Ph.D. candidate, and Lee on a single CaFe2As2 crystal two micrometers in diameter that was synthesized at Canfield’s lab at the Ames Laboratory:

In addition to the crystal’s large ability to recover, the team saw evidence of calcium iron arsenide’s ultra-high strength and significant fatigue resistance, which would guarantee structural performance and integrity if used as a structural material. They also noted another unique property when testing CaFe2As2 at extremely cold temperatures. The existence of shape-memory effect was confirmed when tested at temperatures as low as 50 Kelvin, or about -370 degrees Fahrenheit. This could lead to the development of technologies that change shape at low temperatures for use in deep space travel.

But Lee is most excited about what these discoveries could indicate about other materials in the same family as calcium iron arsenide.

“Our results can be applied to more than 400 similar materials. This discovery opens up an entirely new area of research on superelastic materials,” Lee says. “We see great potential for our findings to be applied by fellow scientists in future research and by industry in the development of new technologies.”

The findings were published in Nature Communications online on Oct. 20 in a paper titled “Superelasticity and Cryogenic Linear Shape Memory Effects of CaFe2As2.” Graduate and undergraduate students in Lee’s lab performed much of the mechanical property measurement and testing for the paper: materials science and engineering (MSE) doctoral candidates John Sypek and Keith Dusoe and MSE undergraduate researchers Hetal Patel and Amanda Giroux, are co-authors on the paper, along with Seok-Woo Lee, Hang Yu, Alan I. Goldman, Andreas Kreyssig, Paul C. Canfield, Sergey L. Bud’ko, and Christopher R. Weinberger.

The research at UConn’s Department of Materials Science and Engineering & Institute of Materials Science was supported by UConn Start-up Funding and the UConn Research Excellence Program. Lee credits this institutional support with helping him win a 2016 Early Career Faculty Grant from NASA’s Space Technology Research Grants Program (grant number NNX16AR60G).

“UConn’s Department of Materials Science and Engineering is among the top programs in the country, and since Seok-Woo came to UConn three years ago, he has shown that he is one of our most creative and productive early career faculty,” says Radenka Maric, vice president for research and professor in the department. “Not only a preeminent researcher, Seok-Woo engages with students at the graduate and undergraduate levels. We are thrilled that the collaboration between Seok-Woo, his talented students, and acclaimed scientists from the Department of Energy’s Ames Laboratory and other esteemed institutions has yielded such remarkable results. This is a testimonial to his commitment to both cutting-edge research and his role as an educator.”

DOE’s Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our time.