3-D printing, also known as additive manufacturing, is a process of making three-dimensional solid objects from a digital file. In this additive process, an object is created by laying down successive layers of material until it is completed.

The technology is rapidly gaining hold in the manufacturing industry, where manufacturers are able to print parts at a fraction of the cost of traditional methods. It is also now becoming more affordable for consumers and small businesses, and UConn students have a variety of opportunities to learn how to use the equipment, ranging from in-class projects to walk-in labs and maker spaces where they can experiment and practice.

One of these walk-in labs, located in the School of Business, is the OPIM Innovate Lab, where students can learn the basics of how an idea can go from concept to reality through 3-D printing from a digital file in a matter of hours. As part of the walk-in service provided by OPIM Innovate, ‘tech kits’ are available at three different levels of difficulty, according to the users’ level of experience with the technology.

Student photographer Garrett Spahn ’18 (CLAS) stopped by the lab recently. Here’s what he found.

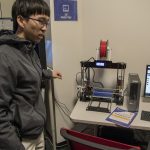

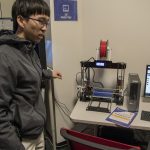

Nathan Hom '19 (ENG/BUS), a junior majoring in management and manufacturing engineering, creating a 1.5 inch by 1.5 inch block on a 3-D printer in the OPIM Innovate Lab. The process begins with making a 3-D model, either through a modeling software or by scanning an object. (Garrett Spahn '18 (CLAS)/UConn Photo)

Alpay

Nathan Hom '19 (ENG/BUS), a junior majoring in management and manufacturing engineering, creating a 1.5 inch by 1.5 inch block on a 3-D printer in the OPIM Innovate Lab. The process begins with making a 3-D model, either through a modeling software or by scanning an object. (Garrett Spahn '18 (CLAS)/UConn Photo)

Nathan Hom '19 (ENG/BUS) creating a 1.5 inch by 1.5 inch block in the OPIM Innovate Lab using a program called Solid Works. (Garrett Spahn '18 (CLAS)/UConn Photo)

Alpay

Nathan Hom '19 (ENG/BUS) creating a 1.5 inch by 1.5 inch block in the OPIM Innovate Lab using a program called Solid Works. (Garrett Spahn '18 (CLAS)/UConn Photo)

Nathan Hom '19 (ENG/BUS), works with a 3-D printer in the OPIM Innovate Lab. (Garrett Spahn '18 (CLAS)/UConn Photo)

Alpay

Nathan Hom '19 (ENG/BUS), works with a 3-D printer in the OPIM Innovate Lab. (Garrett Spahn '18 (CLAS)/UConn Photo)

Nathan Hom '19 (ENG/BUS) works with a 3-D printer in the OPIM Innovate Lab. (Garrett Spahn '18 (CLAS)/UConn Photo)

Alpay

Nathan Hom '19 (ENG/BUS) works with a 3-D printer in the OPIM Innovate Lab. (Garrett Spahn '18 (CLAS)/UConn Photo)

A series of wrenches 3-D printed by Nathan Hom '19 (ENG/BUS) in the OPIM Innovate Lab. These wrenches are fully functional. (Garrett Spahn '18 (CLAS)/UConn Photo)

Alpay

A series of wrenches 3-D printed by Nathan Hom '19 (ENG/BUS) in the OPIM Innovate Lab. These wrenches are fully functional. (Garrett Spahn '18 (CLAS)/UConn Photo)

A model of the UConn School of Business printed by a UConn student using one of the three 3-D printers available in the OPIM Innovate Lab. In 3-D printing, the objects are printed layer by layer using a special plastic. (Garrett Spahn '18 (CLAS)/UConn Photo)

Alpay

A model of the UConn School of Business printed by a UConn student using one of the three 3-D printers available in the OPIM Innovate Lab. In 3-D printing, the objects are printed layer by layer using a special plastic. (Garrett Spahn '18 (CLAS)/UConn Photo)

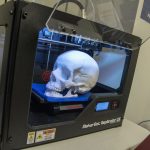

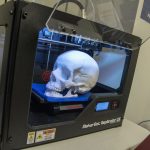

A model of a skull printed by a UConn student using one of the three 3-D printers available in the OPIM Innovate Lab. (Garrett Spahn '18 (CLAS)/UConn Photo)

Alpay

A model of a skull printed by a UConn student using one of the three 3-D printers available in the OPIM Innovate Lab. (Garrett Spahn '18 (CLAS)/UConn Photo)