As personal protective equipment (PPE) shortages persist during the COVID-19 pandemic, a faculty member with the UConn School of Dental Medicine is working to help increase the supply for dental residents, faculty, and other health care workers seeing patients.

Dentists, in particular, are in a high-level exposure group because of the closeness to patients’ mouths—where contamination can easily occur via aerosols from human saliva.

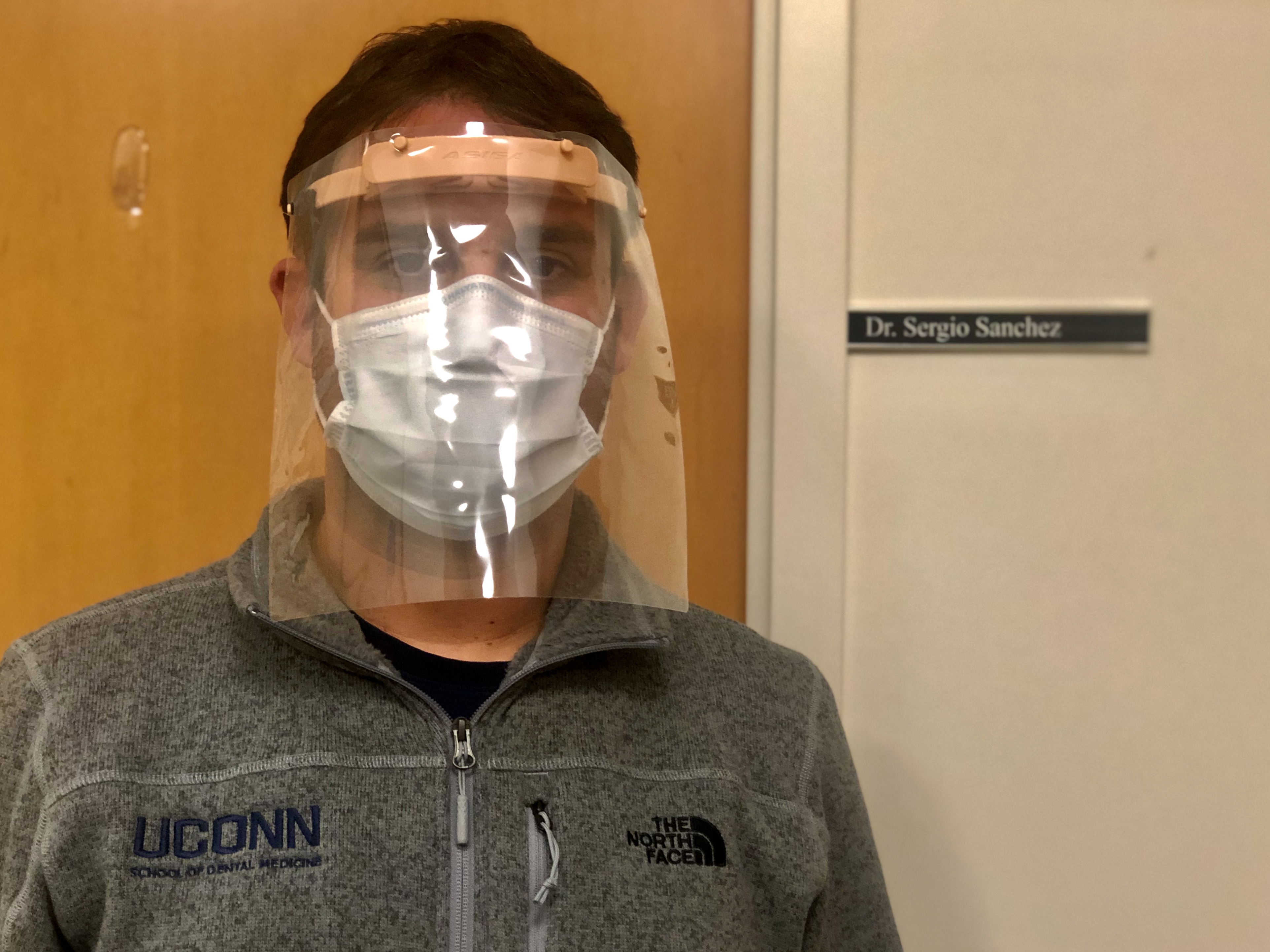

Dr. Sergio Sanchez Velasco, assistant professor and program director of the Advanced Education in General Dentistry (AEGD) residency program, is using 3D printer technology at the dental school to fabricate respirators and face shields for the dental residents seeing emergency dental patients. Sanchez is working alongside first-year AEGD resident Dr. William Garcia.

“There is a lack of PPE for providers and my intention was to start working on them and make them as an alternative in case we run out of resources,” says Sanchez. “We also need high level protection and follow all CDC recommendations.”

Currently, residents at the UConn School of Dental Medicine are seeing patients on an emergency basis – which includes cases of severe toothache, swelling and bleeding, infection, or trauma.

Dental residents and faculty seeing patients have been using disposable PPE and have been working diligently to extend the life of the equipment. Sanchez is determined to ensure the masks and face shields that he prints are made with reusable materials to preserve supply and reduce waste.

Sanchez and Garcia have been working together to research the materials, designs, and filtration systems needed to create the masks and face shields. They have been able to create a handful of reusable prototypes using the 3D printers that are typically used for routine digital dentistry work.

Masks in particular have been a challenge. While Sanchez and Garcia have mastered the design of the mask, they are still working on perfecting the filtration system to ensure the masks have the efficacy of an N95 respirator mask.

“They fit, they work, we just don’t know how well they filter,” says Sanchez. “The mask still needs to be trial-tested to make sure it’s really filtering well.”

Face shields do not need the same level of testing as the masks, but the dentists still encountered a minor bump in the road. Sanchez and Garcia have identified a model that works well on the 3D printer at the dental school; however, the materials needed are not expected to ship for another two weeks due to supply problems caused by the pandemic.

Minor hurdles aside, Sanchez is hoping he will eventually be able to produce enough respirators and face shields for the dental emergency department and have enough left over to supply other areas at UConn Health as needed.

“Production is not as fast as we’d love, but it would be our intention to help as much as possible. We are trying to do the best we can, and we know that those seeing patients are doing a great job,” says Sanchez. “We’re proud of our residents, and we want to make sure that dental is in the most safe environment possible.”