Jeffrey McCutcheon, the Al Geib Professor of Environmental Engineering Research and Education at UConn, is usually busy this time of year studying subjects like membrane separations and filtration. But like many, the director of the Fraunhofer USA Center for Energy Innovation, located in the Innovation Partnership Building at UConn Tech Park, has seen the focus of his work change with the COVID-19 pandemic.

Now, McCutcheon is leading a team that is developing a prototype of an emergency ventilator that could be produced by Connecticut manufacturers to help ease the anticipated shortage of the devices as the novel coronavirus continues to spread across the state.

The project started when Ed Wazer, the laboratory director of the Fraunhofer Center, saw a video from a company in Spain that was building ventilators by using a rotating cam to press a level that squeezes an Ambu bag. Ambu bags are used by medical professionals to provide ventilation to those in respiratory distress.

“The original designers, as well as the people from around the world that are partaking in discussion groups related to the project, have been instrumental in getting the project this far,” says Wazer.

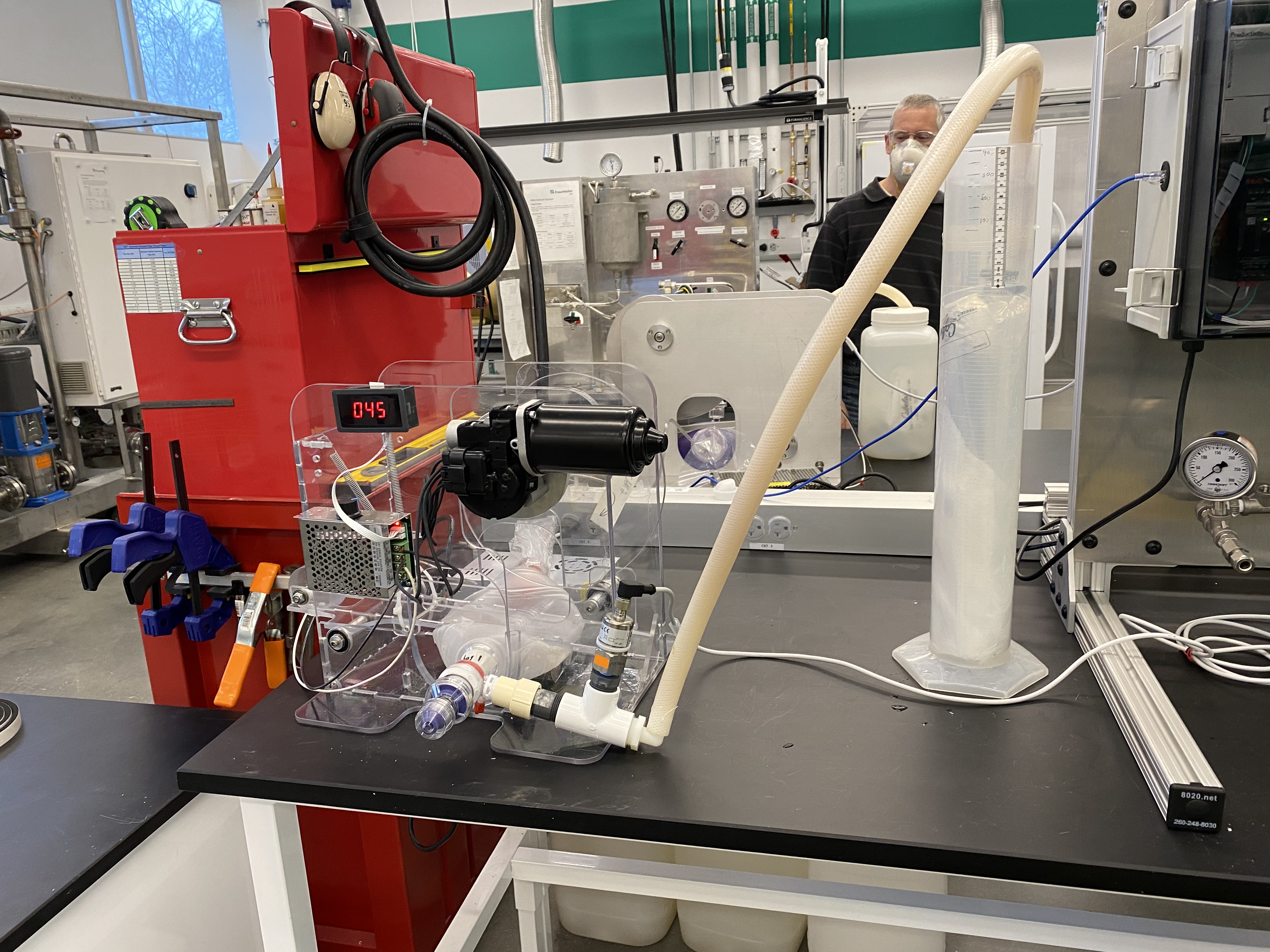

As a first step, the team built a prototype of the ventilator using a number of plastic parts.

“The cam size and shape determines the performance of the ventilator in a lot of ways,” says McCutcheon. “We have been running it for 72 hours at a time and analyzing the data to see if the pressure is stable, and seeing if there is evidence of failure or damage.”

A second generation model was recently completed that is made out of aluminum.

“We added a few more bells and whistles and are testing some more failsafes, which will lead us down the path to exploring an emergency use authorization from the Federal Drug Administration.”

That approval still needs to be gained, but the hope is that with a second prototype developed, that approval could come in a reasonable amount of time.

Implementation to this point would not have been possible without the work of the Mechanical/Glass: Design and Fabrication facility at UConn under the direction of Mark Drobney. The facility is where the parts to the ventilator have been created and improved.

The UConn Fire Department loaned the group an incubation mannequin to help test out the system and also provided Ambu bags with pressure relief valves that will improve the system.

It’s an emergency, and we have to bring all our state resources to bear. — UConn Engineering Professor Jeffrey McCutcheon

McCutcheon’s hope is that the prototype uses parts that would be easy to make by Connecticut manufacturers working in metal or machinery.

“UConn’s role here is not to manufacture ventilators, that is not what we do,” he says.

He believes the right manufacturer could produce ten of these a week without much trouble, and they could be moved from hospital to hospital as the ventilator needs change over time.

“That’s really what we have been thinking about since the beginning and we saw the news reports coming out of Italy and their lack of ventilators,” says McCutcheon. “We wanted to take a device that has been proven somewhere else, make a few adjustments to it and give it our spin. It is not a very complex device, we just devised a way to squeeze an Ambu bag in a very controlled way. It can be made very quickly without a lot of cost or retooling.”

He adds: “It’s a clever, simple approach to produce a rapidly deployable emergency ventilator. If the health care professionals in the state or region saw a shortage is coming based on the models of ICU admittance, they could use these and not start from scratch.”

McCutcheon and Wazer see the development of the model and other efforts around UConn to help in the fight against COVID-19 as part of the mission of the university.

“It’s an emergency, and we have to bring all our state resources to bear,” says McCutcheon. “The state flagship university is an incredible resource of talented students, professors, staff, and administrators with all kinds of skill sets. We get funding from the state, we support the state in its economic mission, and we should support the state in any crisis mission as well.”

“The role of academia, as well as everyone else, is to do what they can to help humanity during this challenging time,” says Wazer. “For those that don’t have direct skills to offer, or are at greater risk from complications, to shelter in place is of great assistance. For those that have skills to offer, it is a critical time to work together to address the challenges that are upon us.”