UConn’s Associate Dean for Research and Industrial Partnerships, S. Pamir Alpay, and Yomery Espinal ’18 PhD (ENG) have published a paper on a novel portable pyroelectric technology in Cell Reports Physical Science with support from the Army Research Laboratory.

Pyroelectric energy research is focused on how to generate energy from heat that would otherwise be wasted in a catalytic chemical reaction.

When pyroelectric materials are heated, their polarization changes, leading to an electron flow that generates energy. These materials are commonly used in household devices like motion sensor lights, which detect body heat to determine when someone is near.

Anytime there is a catalytic reaction, heat is generated. These devices harness that heat and use it as energy. For example, a combustion engine in a car produces heat that, with this kind of technology, could be used to power the electrical functions of the car that otherwise rely on battery power.

The Army Research Lab (ARL) is particularly interested in this technology because it can provide more power with less weight, which is important for soldiers carrying heavy bags.

While scientists have been experimenting with pyroelectric power for decades, the technology proposed in this paper is completely novel.

“Something like that doesn’t exist,” Alpay says. “It would give you the opportunity to recover some things that just go to waste.”

The technology proposed in this publication is portable and has an extended lifetime. It uses on-chip combustion of methanol, a high-energy fuel, to harness energy from the reaction. The pyroelectric material converts waste heat from the reaction to usable power.

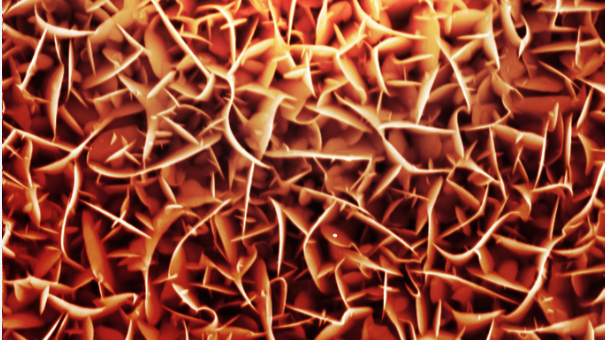

Vapor of a high-energy fuel, in this case methanol, is combusted on a thin, 440 nanometer film on platinized silicon wafers. The device converts the heat from this reaction into pyroelectric power.

Nanostructured iridium oxide is the top electrode and combustion catalyst. Iridium is a dense, corrosion and heat-resistant metal making it an excellent candidate for this application. Iridium oxide is first activated at temperatures as low as 105 degrees Celsius and fully catalyzes methanol to carbon dioxide at 120 degrees Celsius.

This is an advantage compared to platinum-based catalysts, which do not achieve full conversion until 150 degrees Celsius. This means less heat must be applied to the device for it to be fully effective.

This on-chip combustion technology has a 90% combustion efficiency rate.

This technology would be significantly more powerful than lithium-ion batteries, the common rechargeable batteries used in electronics. The energy density of methanol is 22 times greater than a lithium-ion battery.

While this study only provided researchers with a preliminary version of this technology, it can have far-reaching applications.

Pyroelectric power is a clean alternative to fossil fuels and nuclear energy, which still constitute more than 80% of the United States’s power. Thus, this technology has broad energy applications on large and small scales.

Brendan Hanrahan, Ph.D., a staff materials engineer at ARL, led this effort on ARL’s side of the partnership. Hanrahan operated as a critical hinge to bring the ARL and UConn researchers together for this project.

Espinal earned her Ph.D. at UConn and was awarded the Bridge to the Doctorate Fellowship in 2013, which supports members of underrepresented groups in STEM. She began working at the Army Research Lab with Hanrahan during her time in the program and spent two years there. Immediately after graduation, she was offered a position with the Defense Advanced Research Projects Agency (DARPA).

Over the past few years, UConn and ARL have fostered a productive partnership that will likely continue for years to come.

“The key to our successful collaboration is that we play off each other’s strengths,” says Dr. Hanrahan,. “Without one another [Alpay’s] theories would remain theories and we’re just shooting in the dark. So that’s why it’s such a great partnership.”

Follow UConn Research on Twitter & LinkedIn.