The University of Connecticut recently licensed their groundbreaking continuous manufacturing technology for pharmaceutical nanoparticles in support of commercialization to DIANT Pharma Inc. The technology was developed by assistant research professor Antonio Costa and distinguished professor Diane Burgess, from the Department of Pharmaceutical Sciences and co-founders of DIANT Pharma Inc.

Supported through more than $5 million in funding from the Food and Drug Administration, Burgess and Costa have been developing this technology since 2013 and formed DIANT Pharma Inc. in 2019.

“When academic researchers and industry come together, we can find solutions to some of the world’s major challenges,” says UConn Vice President for Research, Innovation and Entrepreneurship, Radenka Maric. “Diane is an internationally renowned scientist, and the success of this team is a prime example of how innovative research from preeminent researchers can transition from an idea in a lab to a technology that can help people around the world.”

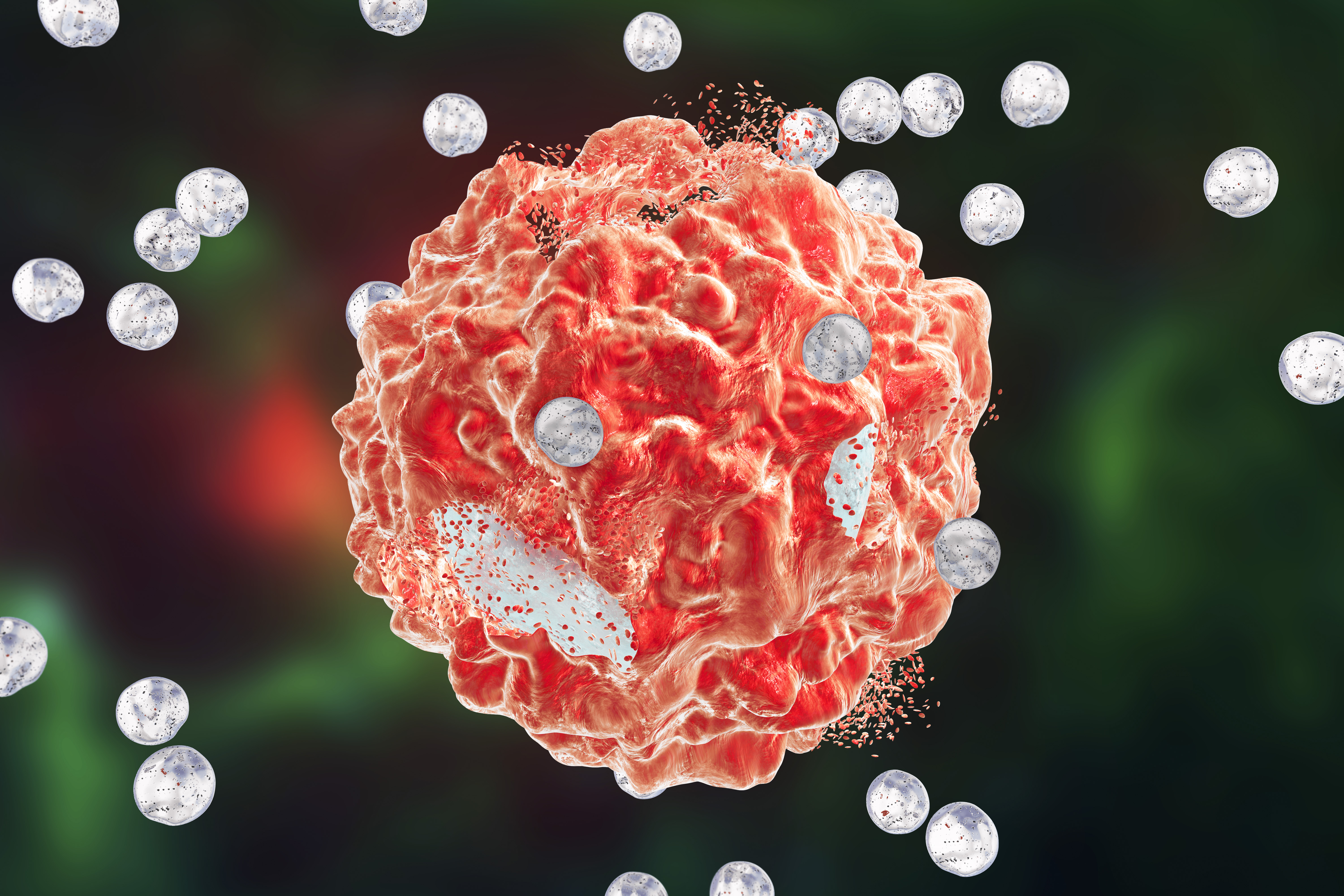

The technology they have developed is a continuous manufacturing system for nanoparticulate drug delivery systems. The technology is specifically designed for liposomal formulations, but is applicable to a wide range of nanoparticles, such as lipid nanoparticles, polymeric micelles and emulsions.

Their continuous manufacturing process has several advantages over conventional batch manufacturing approaches. The system obtains highly controlled particle size. The system offers high-throughput, which can potentially reduce the number of batches per year. It also has a smaller footprint as the system is considerable smaller than a batch process and can occupy less space in a clean room, reducing costs.

By nature of being a continuous process, DIANT Pharma INC’s technology avoids many of the traditional pitfalls of nanoparticle manufacturing. First, it is much more efficient since it can run for longer, while constantly processing raw material into the finished product. In batch manufacturing, the system can only create a set volume of product at a time dictated by the size of the facility’s containers.

“We can make this product less expensive and with much higher quality,” Burgess says.

More Relevant Now Than Ever

As many drug manufacturing operations have moved offshore due to high labor costs in the United States, continuous manufacturing systems like this could offer an affordable solution to U.S.-based companies.

The system monitors for quality at all times and can quickly identify a problem, such as a sudden change in a process parameter.

“We’re continuously checking quality during the entire process,” Costa says.

With batch manufacturing, if there is a problem, the entire batch, potentially hundreds of liters of product, may need to be discarded.

The applications for this technology are particularly relevant right now as the COVID-19 pandemic has led to drug shortages. Quick, high-quality manufacturing could alleviate these shortages by rapidly producing products in short supply.

“Our company is being launched at a time when the need for such technology is really being recognized,” Burgess says. “I think everyone is becoming aware of the importance of this.”

Continuous manufacturing could also be highly beneficial to the rapid development of a COVID-19 vaccine. Once scientists develop an effective vaccine, it will need to be scaled up to produce millions of doses. When a drug is scaled up, it often faces challenges that can take months to years to remedy.

Since continuous manufacturing does not face the same scale up problems as in a batch process, more material can be produced over the same period of time.

“If you use this kind of manufacturing you could reach more people much more quickly,” Burgess says.

The recently licensed technology is ready to be put to work in Good Manufacturing Practice (GMP) facilities. DIANT Pharma Inc. is currently looking for partners to expand the use of this system.

Commercialization Journey

DIANT Pharma’s product offers drug manufacturers a complete system that can decrease cost, time and space while increasing quality.

Several UConn programs have supported this entrepreneurial research team on their journey to commercialize a potentially groundbreaking technology.

With the support of UConn’s National Science Foundation I-Corps site, Accelerate UConn, Technology Commercialization Services and the UConn Technology’s Incubation Program, the team was able to conduct customer discovery and secure patent protection for their innovation.

These programs helped DIANT Pharma refine their business plan, with a robust strategy of quickly getting to market after launch. DIANT Pharma has begun production of their commercial system and inked their first system sale this year. They have also partnered with a company to develop and market laboratory equipment, targeting academia and researchers.

“In the end, it is a turnkey solution to all their nanoparticle drug manufacturing needs,” Costa says.