It’s been said that art imitates life, but a UConn School of Dental Medicine researcher and his team have expanded that reflection to include the observation, “science imitates food” – or, in this case, at least, the research he has been conducting was inspired by a tasty dessert supplement common in most household refrigerators.

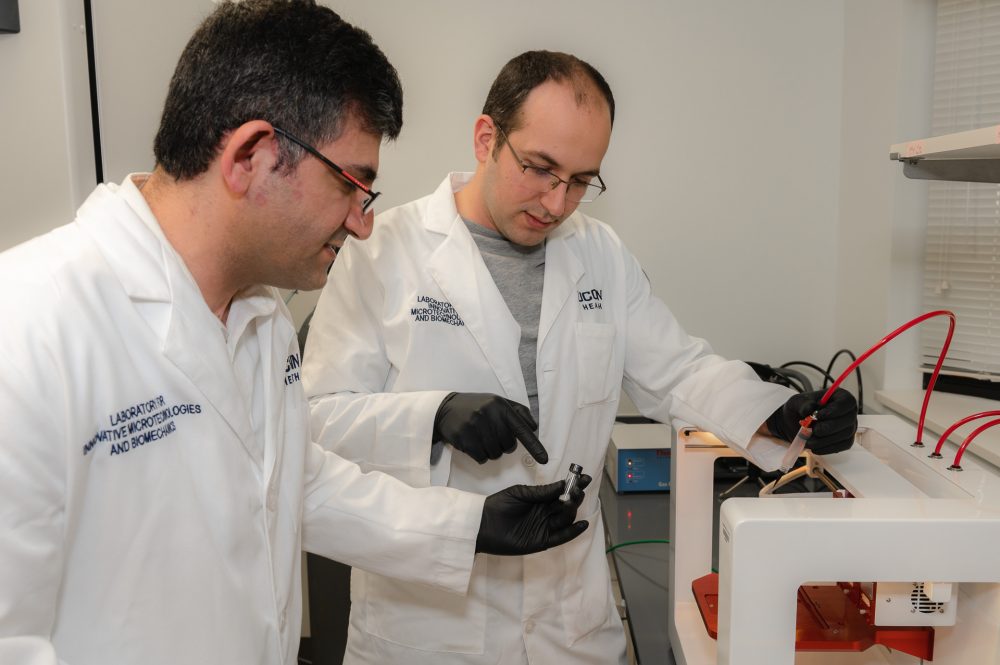

Ali Tamayol, associate professor, UConn Department of Biomedical Engineering, and his team, Dr. Azadeh Mostafavi and Dr. Mohamadmahdi Samandari, had been working on development of bio-inks for 3D printing of implantable scaffolds for regenerative medicine applications. The goal had been to improve tissue regeneration by implanting the scaffold into the tissue defects caused by trauma, surgical procedures and degenerative disease. The team was testing various compounds that might be used to form porous bio-inks, which could be bio-printed and placed in the injured area.

Typically, 3D bio-printed scaffolds are made from hydrogels. However, hydrogel pores are smaller than the size of a cell, limiting the rate of cellular regrowth.

When eating whipped cream or using shaving cream, Tamayol realized that these foams were easy to apply, formed complex shapes, and were highly porous, leading him to conclude that he could produce scaffolding materials that might function in a similar fashion. They started testing biological materials that could be turned into a foam and used to support vascularization, muscle regeneration and function recovery.

Agitating gelatin solutions using a mixer, the researchers created a microbubble-embedded foam that could be used as a colloidal bio-ink. The microbubbles increased the size of the pores in the bio-ink, and improved its printability compared to regular gelatin-based bio-inks.

Defects were created in mice using a punching tool, and the 3D printed foam scaffolds were placed in the area where the tissue had been removed. In initial tests, new blood vessels formed, and in subsequent testing, the bio-ink was placed in more challenging injury models where muscle had been volumetrically damaged. Within eight weeks, the team found that muscles had regenerated, and lost function had been restored.

“We knew that the regenerative abilities of most scaffolding materials we tried was limited, and that we needed to find more efficient materials and enlarge the pores for successful regeneration,” Tamayol says. “Egg whites may not be the best building material, but proteins are extremely useful in this process. The scaffolds formed through foaming of a gelatin-based solution are highly porous and easy to manufacture. These scaffolds can be produced using stationary printers or be printed directly inside patients’ bodies by portable 3D bio-printers.”

This foundational research, Tamayol adds, has put UConn on the radar for other researchers and labs studying similar interventions. He established a start-up company to continue testing and working on this strategy of clinical implementation for regeneration of defected tissues. Commercial production, he stresses, is likely three to four years away, and will follow significant testing and clinical trials. Currently, his team is working with Dr. Nassim Annabi’s lab at UCLA, and Dr. Indranil Sinha’s lab at Brigham and Women’s Hospital.

A paper Tamayol co-wrote with Samandari detailing their research has been accepted in the scientific journal Applied Physics Review, and another paper detailing additional trials is now in preparation.

“We’ll move into testing the benefits of the foam for bone and skin regeneration, but are quite excited about the potential for these materials and the many possible ways they might eventually be used in patients suffering from tissue injuries,” Tamayol reflects. “It’s funny to think that whipped cream on my breakfast waffles led to this discovery, but sometimes it’s the simple things around us that lead to great creative ideas.”