UConn’s collaboration with the Air Force Research Laboratory (AFRL) is launching a new program consisting of eight interconnected projects focused primarily on photonics, magneto-optics, metamaterials, and detectors in the aerospace industry.

AFRL leaders, including Chief Technology Officer and UConn alum Tim Bunning ‘87 (ENG), ’88 MS, ’92 Ph.D., visited UConn Tech Park on Nov. 11. They kicked off the third phase of the Air Force’s collaboration with the University, known as Project Daedalus – a partnership between UConn, the AFRL, and industry partners formed to tackle aerospace manufacturing challenges.

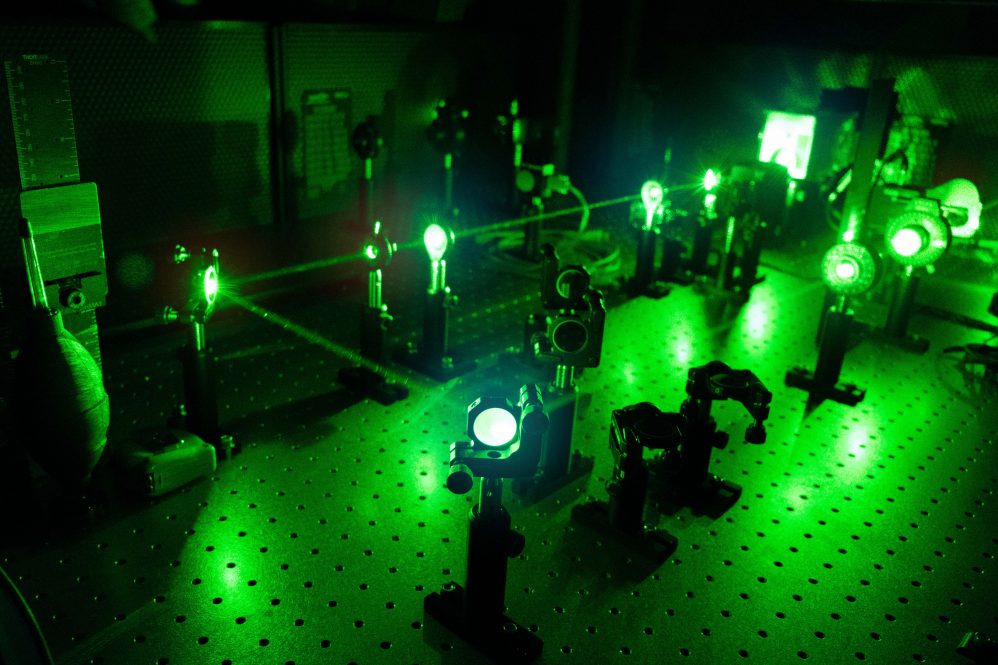

The third phase is funded by a $4.7 million contract, and is entitled “Multiscale Modeling and Characterization of Metamaterials, Functional Ceramics and Photonics.” It seeks to explore and advance the understanding of electronic, photonic, magnetic, and multiferroic variable space, focusing on relating form and function across several materials systems.

“Certain materials and composites interact with external forces in a unique way,” says S. Pamir Alpay, Executive Director of UConn Tech Park and the primary investigator for the program. “For example, a group of ceramics produce an electrical current with changes in temperature, mechanical loading, or when interacting with light. Our goal in this program is to characterize the behavior of such smart materials and components and explore device applications for the U.S. Air Force.”

The contract will fund eight new projects over a three-year period from 2021-2024, supporting the work of eight faculty members, 17 graduate students, and one research scientist. The contract increases total funding of Project Daedalus to $18 million since the collaboration began in 2018.

“This new contract moves us into the next phase of a partnership that has helped propel UConn forward as top research university,” says Radenka Maric, Vice President for Research, Innovation, and Entrepreneurship. “UConn’s work with the Air Force Research Laboratory on Project Daedalus has provided a platform for our faculty and students to explore their intellectual depth and capacity within the aerospace sector.”

Project Manager Alexandra Merkouriou ’15 (ENG), ’19 MS says that the third phase is a continuation with the ARFL that provides great opportunity for a comprehensive outlook into a growing field in aerospace manufacturing.

“This is a relatively new field for industry, the Air Force and military with much yet to be investigated,” Merkouriou says. “This is UConn’s opportunity to define a new field of engineering and technology.”

Phase 3 of Project Daedalus offers UConn students and faculty the chance to define and explore how fundamental concepts involving the propagation of electron energies and magnetic fields can improve infrared sensors and device development. While Phases 1 and 2 focus mainly on traditional aerospace manufacturing techniques, Phase 3 will offer a comprehensive view of how novel materials can be implemented in next generation devices.

“There are high expectations for Phase 3 of the Daedalus program,” says Mike McConney, the Senior Materials Research Engineer and lead of the Electronic Materials and Processing Team at the AFRL. “A uniquely qualified team aimed at exploring the intersection of ferroic materials and dynamic photonics is a recipe to reveal powerful mechanisms to manipulate light.”

Researchers will be able to create atomistic models of materials to calculate characteristic properties and interactions, synthesize these materials, measure their properties to validate the models, and implement the materials in prototype devices. This will provide a sweeping view of the capabilities of this field that both the Air Force and industry can use to advance technology going forward.

“A strong national S&T ecosystem in high performance advanced materials for multidisciplinary photonic, electronic, and/or structural applications is critical for future national security and advanced commercial needs,” Bunning says. “Underpinning success requires the development of the next generation scientific tools and brainpower to ensure the ability to manufacture and introduce next generation complex material systems into the commercial ecosystem. AFRL applauds the effort of Project Daedalus in leaning forward to couple industry, academia, and the Department of Defense together to build the foundation by de-risking the efforts through collaboration at the intersections.”

Alpay lauded the work that Merkouriou has done as project manager in facilitating the relationship between UConn, the AFRL, and the industry partners involved in Project Daedalus.

“We are fortunate that Alexandra is helping us in coordinating this multifaceted collaboration with AFRL,” says Alpay. “Her experience working in the industry with GE Industrial Solutions and M Cubed Technologies is a great asset in managing Project Daedalus.”

The following UConn faculty are involved in the program:

Pamir Alpay, Board of Trustees Distinguished Professor, Materials Science and Engineering; Osama Bilal, Mechanical Engineering; Bryan D. Huey, Materials Science and Engineering; Menka Jain, Physics; Bahram Javidi, Board of Trustees Distinguished Professor, Electrical and Computer Engineering; Thomas Katsouleas, Electrical and Computer Engineering; Serge Nakhmanson, Materials Science and Engineering; Volkan Ortalan, Materials Science and Engineering; Ilya Sochnikov, Physics