University of Connecticut Professor of Biomedical Engineering Liisa Kuhn credits Willy Wonka’s Everlasting Gobstopper for inspiring her work on designing bone grafts, growth plate repair gel—and most recently—breast prosthetics.

“The Gobstopper candy has all these layers, and each layer lets them experience a different course of a meal,” says Kuhn, who has a dual appointment with the School of Dental Medicine and the College of Engineering. “Similarly, in my own research, I’m working with multilayered structures that provide timed release of multiple factors to improve bone and cartilage healing.”

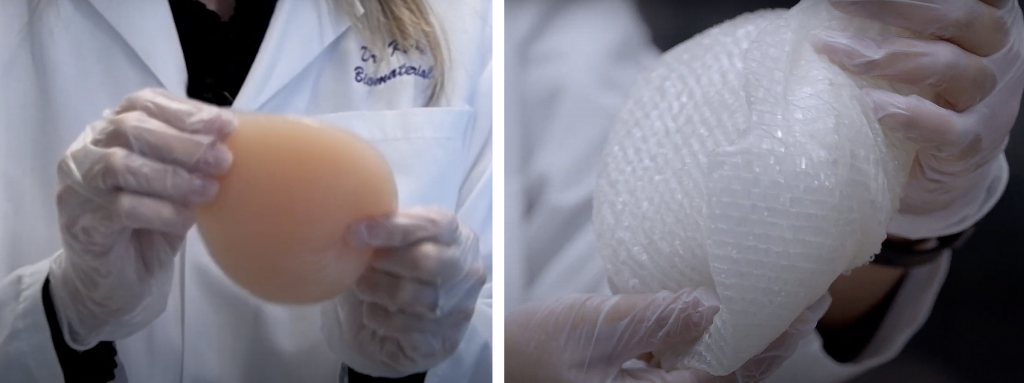

Now in her 22nd year at UConn, Kuhn is directing the Beekley Lab for Biosymmetrix, where she’s developing a patent-pending process for using a 3D bioprinter to “print” personalized breast prosthetics for cancer survivors. The multi-layered structure of the prosthetic will improve the quality and comfort of people’s lives after breast cancer.

Kuhn came up with the idea for the breast prosthetic when her colleague Jan Figueroa, administrative program assistant at UConn Health, underwent a unilateral mastectomy following a battle with breast cancer. Figueroa chose not to undergo reconstructive surgery for an implant and opted for a non-implanted breast prosthetic instead.

“I was offered two choices of prosthetics. Both were uncomfortable, moved all over, were never symmetrical, did not breathe, and did not form to my body,” Figueroa recalls. “I told Liisa what I was going through with a shop my insurance carrier recommended, and how I was treated.”

Kuhn listened.

“I thought – I can do something about that. I’m in the School of Dental Medicine and I know dentists are taking digital images of patients’ teeth and using computer aided design and computer aided manufacturing to create a crown, sized exactly to the exact shape and size needed,” she says. “So why couldn’t we apply the same idea and create customized prosthetics?”

Kuhn learned to take 3D photos of a woman’s chest and worked with a CAD designer to convert the images to a file that could be 3D printed. Those with a single mastectomy, such as Figueroa, would have their remaining breast scanned while in a bra and digitized and “mirror imaged” in the software against the surgery side, producing a 3D model that fits perfectly against her chest with the correct size.

3D bioprinting is used by several faculty members at UConn Health for creating small pieces of cartilage, liver, or heart, but Kuhn needed something much larger to 3D print breast prosthetics. Oncologists Dr. Susan Tannenbaum and Dr. Christina Stevenson from the Carole and Ray Neag Comprehensive Cancer Center, and the Dean of the College of Engineering supported Kuhn’s application to the Connecticut Breast Health Initiative, and it was funded in 2021, resulting in the purchase of a specialized, four-foot-tall bioprinter platform to benefit the patients of the Neag Comprehensive Cancer Center.

Unlike a regular 3D printer that fabricates objects using a solid plastic filament, the bioprinter extrudes an elastomer gel that results in a lightweight, flexible, and porous product with an open cell foam design. She coined the name of the process “Biosymmetrix.”

And Figueroa received the first Biosymmetrix prosthetic. “With a few modifications, Dr. Kuhn’s prosthetics are shaping up—no pun intended—to give all of us breast cancer survivors back our confidence to wear clothing we could not prior to this,” she says. “Now, I can comfortably wear a t-shirt or anything I was told I should forget on doing.”

“With a few modifications, Dr. Kuhn’s prosthetics are shaping up—no pun intended—to give all of us breast cancer survivors back our confidence to wear clothing we could not prior to this. Now, I can comfortably wear a t-shirt or anything I was told I should forget on doing.” — Jan Figueroa, cancer survivor

Since completing Figueroa’s prosthetic, more than 80 women have requested a customized breast prosthetic from Kuhn’s lab, however she’s only been able to provide one for 14 women so far.

As Kuhn has learned through “thousands of failed attempts,” depositing the thin elastomer with an intricate lattice-like pattern with 200-some layers, has deemed difficult. Like a hot glue gun, the gel often doesn’t stay in a unform size, and any build-up can cause blobs of unwanted filament. In addition, a single print can take eight hours to complete.

“We are helping the bioprinter company to optimize their robot arm’s capabilities because the technology for large format gel printing is not fully developed, and that’s why it’s not being done by others throughout the world, yet,” she acknowledges.

Once the process is perfected, Kuhn hopes to establish a 3D printing “farm” and catch up on the backlog of orders.

“Dr. Kuhn cared about me as a person, not such a test subject, and she heard me,” Figueroa says. “We became not just two people who worked in the same building, but I like to say, friends. Liisa is now part of my group that took me from diagnosis, to treatment, to surgery, to giving me back confidence and self-esteem.”

Kuhn, whose other research interests focus on drug delivery and bone regeneration, including developing customized bone grafts with controlled drug release to rejuvenate bone healing in older women, hopes the prosthetics are another way to help women live more comfortable lives.

“Women’s positive response to the prosthetics makes all the hard work worthwhile,” Kuhn says. “I feel so lucky to have found a meaningful way to use my engineering skills to help these women.”