The conventional way of making dentures can be tedious. The process can take multiple patient visits and involve complicated laboratory work and potential need for remakes or relines.

At the UConn School of Dental Medicine, it’s a different story when it comes to the creation of dentures. The School is no stranger to embracing modern dentistry—virtually all disciplines have implemented digital pathways and technology in both the educational and patient care programs.

The prosthodontics department is just one example of how UConn is adopting the latest technology in dentistry.

“We used to use conventional techniques to create dentures,” says Dr. Foteini Touloumi, associate professor of prosthodontics at the UConn School of Dental Medicine. “It was tedious and required a lot of work in the laboratory, so in 2021 we decided to start utilizing digital technology to fabricate dentures.”

Conventional to Digital

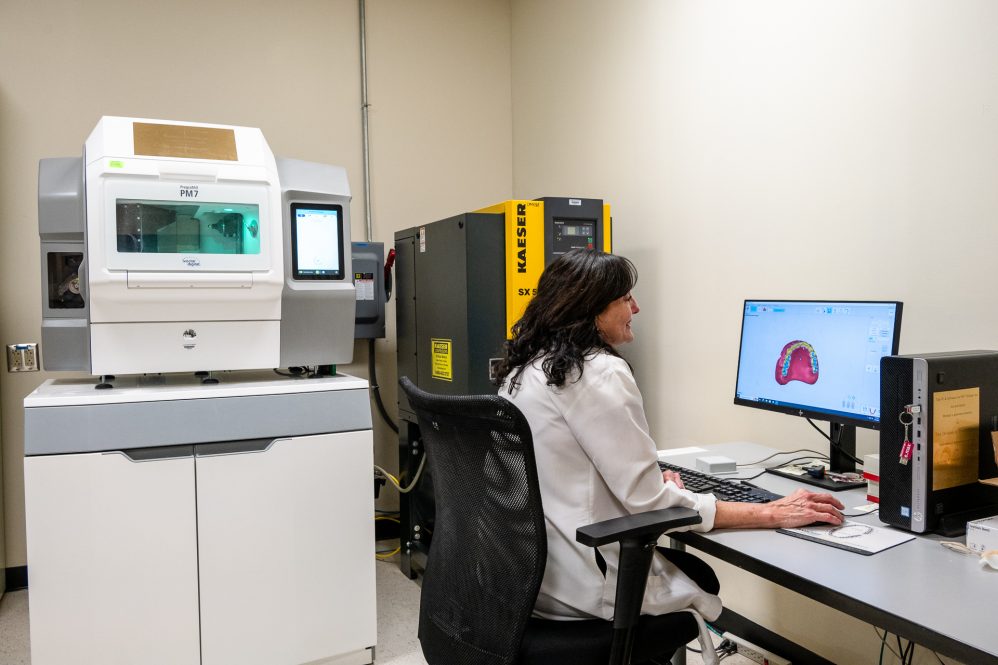

The dental school utilizes a “partial” digital workflow, meaning there are steps done in the laboratory and through digital technology—which includes subtractive/milling manufacturing techniques and 3D printing.

From a public health perspective, digital dentistry has a lot of potential, Touloumi says. Digitizing workflows can be easier than conventional methods and much more cost effective and accessible, with less labor required.

Most importantly, though, incorporating digital technology can result in better patient outcomes.

“They get a better fitting denture,” says Touloumi. “It’s an acrylic material, but it’s less porous, so less retentive to bacteria. There’s also a digital record of the dentures, so we can press a button and make a brand new one if the patient loses the denture.”

Patient Success

Digital dentistry has been a gamechanger for patient care in the prosthodontics department. Technology in dentistry allows for enhanced versatility for both the patient and the provider, allowing for more effective and efficient approaches to diagnosing the patient and treating accordingly.

Kathy from Thomaston originally came to UConn because the cost of care was significantly less than care from a private dentist. Kathy needed several tooth extractions and the removal of bony overgrowths to prepare her mouth for dentures.

With all the dental issues that needed to be addressed, Kathy’s journey to a brighter smile was a long one. When it came to the final product—a new set of dentures—the process was quick and painless.

Using digital technology, providers at UConn were able to seamlessly fabricate a set of dentures that were custom made for Kathy, considering her complex dental history.

The outcome was “a great pair of dentures that fit incredibly well,” says Kathy.

“I feel great about digital dentistry, as it created a pair of dentures that look realistic and fit very well,” Kathy says. “Compared to my old partial dentures they are a 100% improvement.”

An Enhanced Learning Experience

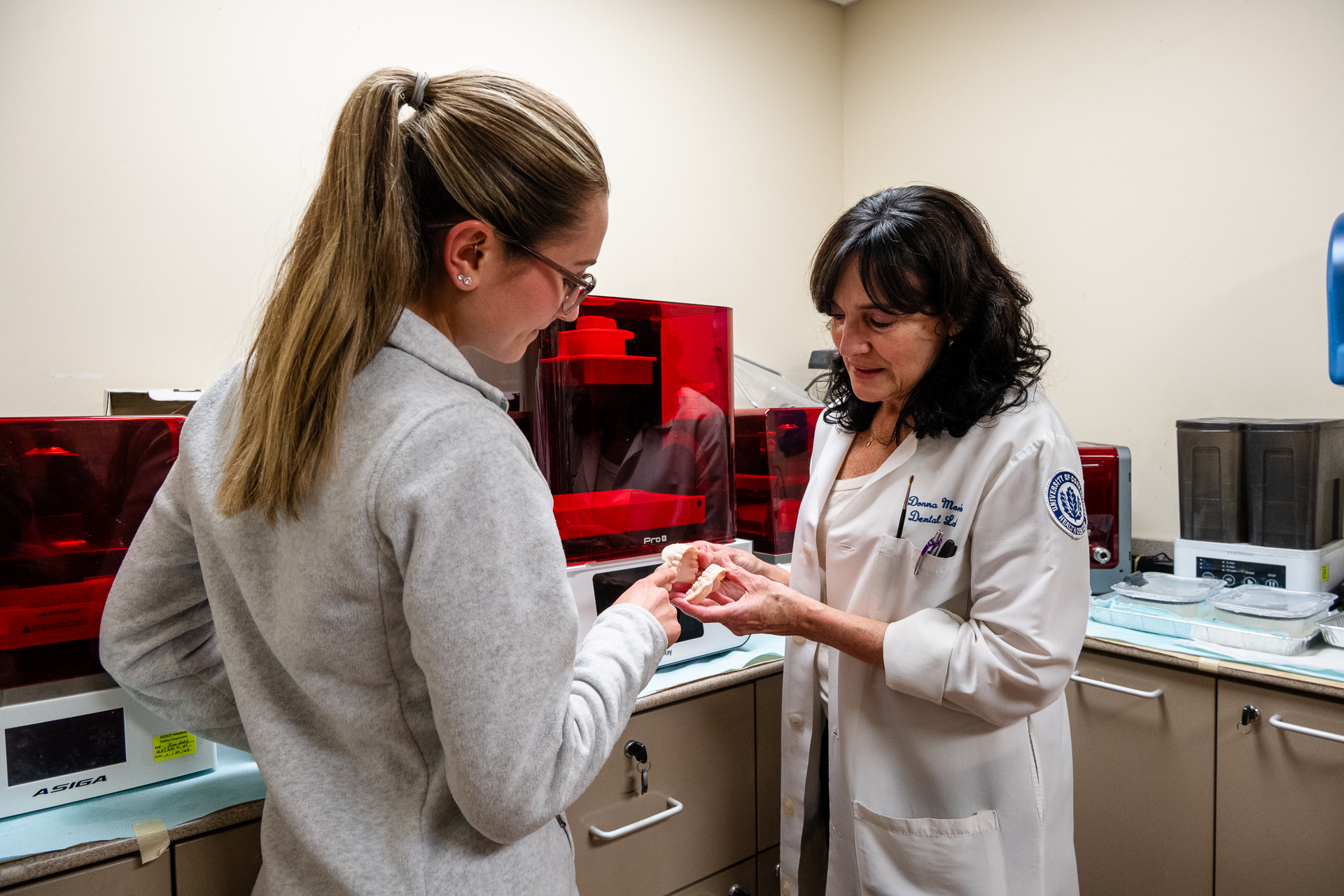

Not only does digital dentistry benefit patients, but it offers a unique learning experience for students and residents.

Dr. Audrey Brigham is a first-year prosthodontics resident at UConn. As a graduate of the School of Dental Medicine, Brigham was drawn to UConn’s top-of-the-line prosthodontics program because of the advanced technology used in the laboratory and in chairside patient care.

Brigham’s desire to go into prosthodontics was inspired by her interest in treatment planning. Prosthodontics is also an ever-changing field, always looking “three steps ahead,” Brigham says.

“Prosthodontics is a field that has evolved so much and has the capacity to evolve even more in the future,” Brigham continues. “Especially in the aspect of digital.”

The prosthodontics department at UConn puts a heavy emphasis on modern dentistry and the learning experience. The dental school has its own mills, 3D printers, and intraoral scanners for patients that can’t tolerate impressions— all available for students and residents to use.

The switch from fully conventional methods of fabricating dentures to a partially digitized workflow has given students and residents the best of both worlds, significantly enhancing the learning experience.

“We have top of the line machines, products, licenses, and digital planning software,” says Brigham. “We also encompass everything— we do conventional, we do digital, and we are always up to date on current research.”

Brigham continues, “We are learning how to use the intraoral scanners, we’re learning when patients may or may not be good candidates for digital.”

At UConn, learning digital dentistry starts at the pre-clinical level. Brigham’s dental school class was the first class to experiment with digital dentures. Students typically fabricate three dentures before graduation utilizing the digital workflow.

No matter where students go— prosthodontics, orthodontics, or general dentistry – the integration of digital dentistry at a pre-clinical level in the prosthodontics department at UConn gives students a leg up to meet the changes in the field.

“The field of dentistry is evolving immensely, and UConn is doing a good job trying to teach their students from the preclinical stage before they graduate to prepare for what the field of digital dentistry will look like in the future,” Brigham says.