The University of Connecticut is one of several leading research institutions collaborating with the Toyota Research Institute to accelerate the design and discovery of advanced materials using artificial intelligence and machine learning.

The Toyota Research Institute (TRI) announced March 30 that it is investing $35 million to support the initiative over the next four years in an effort to revolutionize materials science and identify new advanced battery materials and fuel cell catalysts that can power future zero-emissions and carbon-neutral vehicles.

It is extremely likely there are new and potentially much better functional polymers out there waiting to be discovered. Our goal is to accelerate the discovery process by using virtual screening methods … so that potential new polymers may be identified before they are made. — Rampi Ramprasad

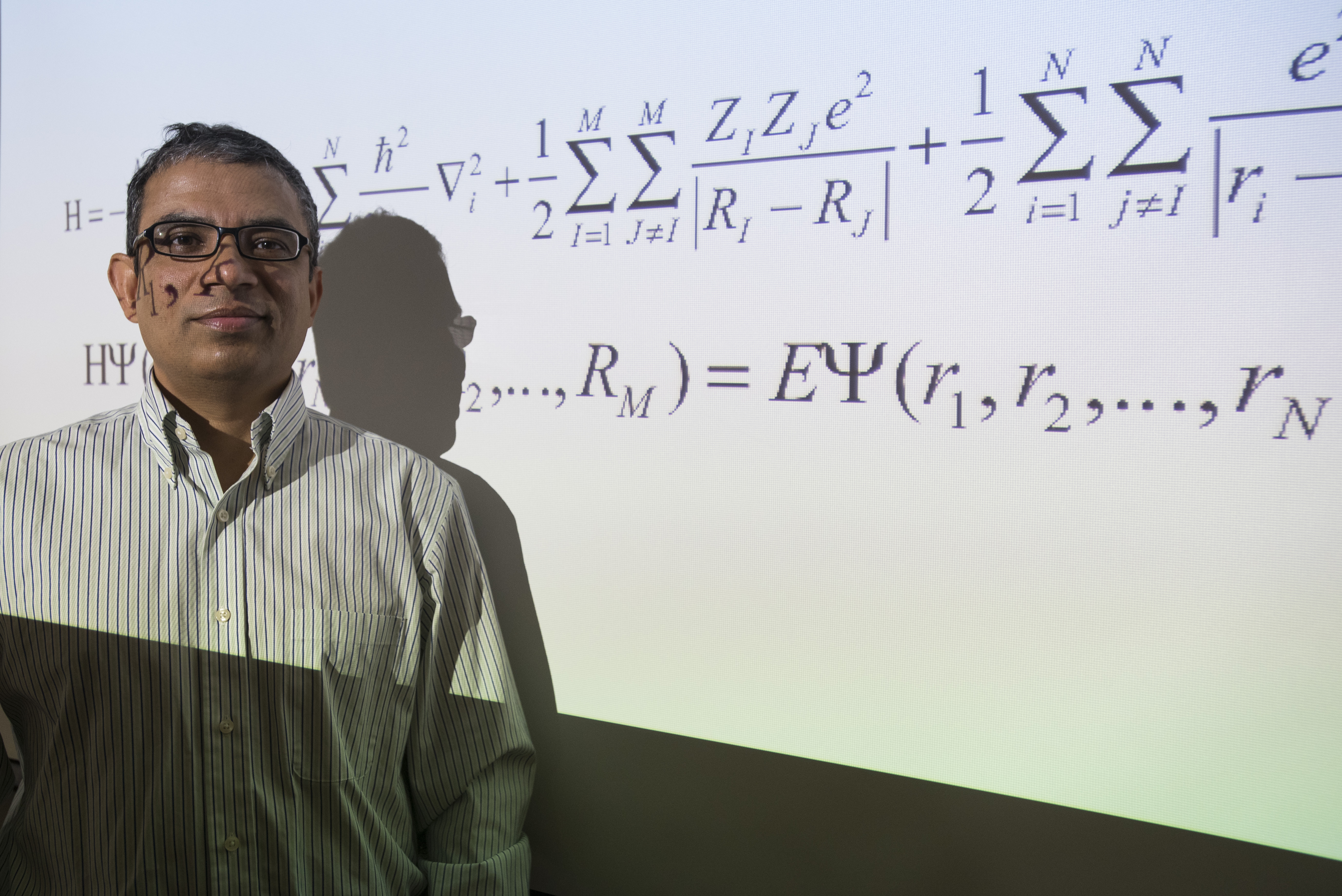

UConn materials scientist Ramamurthy “Rampi” Ramprasad is leading the effort at UConn. Ramprasad’s lab will work to identify new polymers using quantum mechanical computations and data-driven machine learning. Because of their flexible chemical compositions, polymers are impressive when used as insulators, semiconductors, and permeable membranes. They also are safe, inexpensive to produce, and light. As such, they hold the potential for broader use in energy storage applications such as rechargeable batteries and fuel cells.

“Given the nearly infinite chemical compositions for polymers, it is extremely likely there are new and potentially much better functional polymers out there waiting to be discovered,” says Ramprasad, a professor in the School of Engineering. “Our goal is to accelerate the discovery process by using virtual screening methods powered by advanced computations and machine learning so that potential new polymers may be identified before they are made.”

Other institutions participating in the initiative include Stanford University, the Massachusetts Institute of Technology, the University of Michigan, and the University at Buffalo. The U.K.-based materials science company Ilika is also a research partner, and there may be others. TRI is in ongoing discussions with additional collaborators.

“Toyota recognizes that artificial intelligence is a vital basic technology that can be leveraged across a range of industries, and we are proud to use it to expand the boundaries of materials science,” said TRI Chief Science Officer Eric Krotkov. “Accelerating the pace of materials discovery will help lay the groundwork for the future of clean energy, and bring us even closer to achieving Toyota’s vision of reducing global average new-vehicle CO2 emissions by 90 percent by 2050.”

The research will merge advanced computational materials modeling, new sources of experimental data, machine learning, and artificial intelligence in an effort to speed up the development of new materials, a process that historically has been measured in decades. The institutional research programs will follow parallel paths, working to identify new materials for use in future energy systems as well as to develop tools and processes that can accelerate the design and development of new materials more broadly.

The Toyota Research Institute is focusing on three key areas as part of the initiative:

• The development of new models and materials for batteries and fuel cells;

• Broader programs to pursue novel uses of machine learning, artificial intelligence, and materials informatics approaches for the design and development of new materials; and

• New automated materials discovery systems that integrate simulation, machine learning, artificial intelligence, and/or robotics.

Ramprasad’s lab has spent the past several years painstakingly building an online polymer genome knowledge base for a data vault the research team created called Khazana. The Khazana platform, which is publicly accessible, allows scientists to search for potential polymers with specific properties. Polymers are large molecules made up of many repeating chemical building blocks. A common example of a polymer type is plastics, which can be chemically altered and easily manufactured for a variety of different applications from soda bottles to deck chairs to garbage bags.

The novel computational method created by Ramprasad’s research team applies basic quantum mechanics to calculate the atomic and electronic structures of different polymers. This information is then used to “train” a machine learning model to make ultra-fast predictions of properties of new polymers. The machine learning model recognizes polymers based on their numerical representations or “fingerprints.” With this approach, materials scientists can quickly predict the electronic properties of a new polymer, such as its band gap (the amount of energy it takes for an electron to break free of its home atom in the polymer), and its dielectric constant (a measure of the effect an electrical field has on the polymer). Those bits of information, and other relevant information that will be incorporated into the system as part of the TRI initiative, are crucial to scientists looking to create new materials that will improve electrochemical energy storage devices like fuel cells and batteries.

Accelerating materials science discovery represents one of four core focus areas for TRI, which was launched in 2015 with mandates to also enhance auto safety with automated technologies, increase access to mobility for those who otherwise cannot drive, and help translate outdoor mobility technology into products for indoor mobility.