Jon Balyeat ’27 (ENG) is taking a big bite out of one of dentistry’s biggest challenges: how to test new treatments without relying on costly, time-consuming clinical trials.

The biomedical engineering major is designing a mock human mouth – an device that mimics the complex conditions inside the oral cavity – to help researchers evaluate antimicrobial agents, implants, and regenerative therapies in the lab.

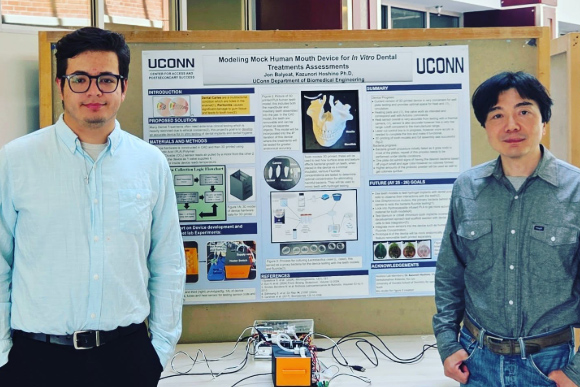

With support from the Center for Access and Postsecondary Success (CAPS) and his advisor, Associate Professor of Biomedical Engineering Kazunori Hoshino, Balyeat spent eight weeks this summer bringing the mouth to life – tooth by 3D-printed tooth as a CAPS Research Scholar.

He completed this project during the 13th annual CAPS Research Summer – a component of the multi-year, year-round programming provided for scholars to excellently prepare to be graduate students.

“Our culturing device aims to mimic the temperature, CO₂ levels, and geometry of a human mouth for optimal lab testing of dental treatments like implants and toothpaste, thus reducing the dependency on clinical trials, which have all sorts of logistical and ethical challenges,” Balyeat says. “It’s a powerful tool for advancing regenerative dentistry and antimicrobial testing.”

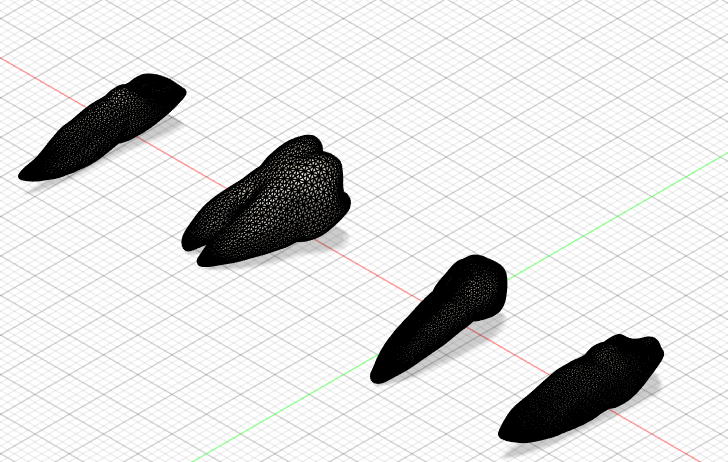

Balyeat and Hoshino first designed the chamber and jaw assembly in computer-aided design. Next, they used a 3D printer to create the device using a biodegradable and biocompatible plastic called polylactic acid (PLA). PLA is made from renewable plant sources and softens when heated and hardens when cools, making it an ideal material for modeling. Some PLA teeth inside the device can be detached for individual, site-specific studies.

The device includes a removable well plate for high-throughput testing, an embedded heat sensor for closed loop temperature control and gas composition, and an integrated heater and air-pump. The unit and all electrical components will be placed inside an incubator.

To begin testing, researchers will colonize the mouth with naturally occurring oral bacteria Lactobacillus casei or Streptococcus mutans to study how microbial growth responds to different fluoride gradients and materials. Balyeat also will test how stem cell implants, calcium phosphate “doped” 3-D printed teeth, and even tissue-mimicking spinach leaves behave inside his mock mouth device.

“We want to know whether they survive, grow, or respond to things like temperature, pH, or bacteria,” Balyeat says. “It’s part of a broader effort to develop regenerative dental treatments that could one day restore natural tooth function.”

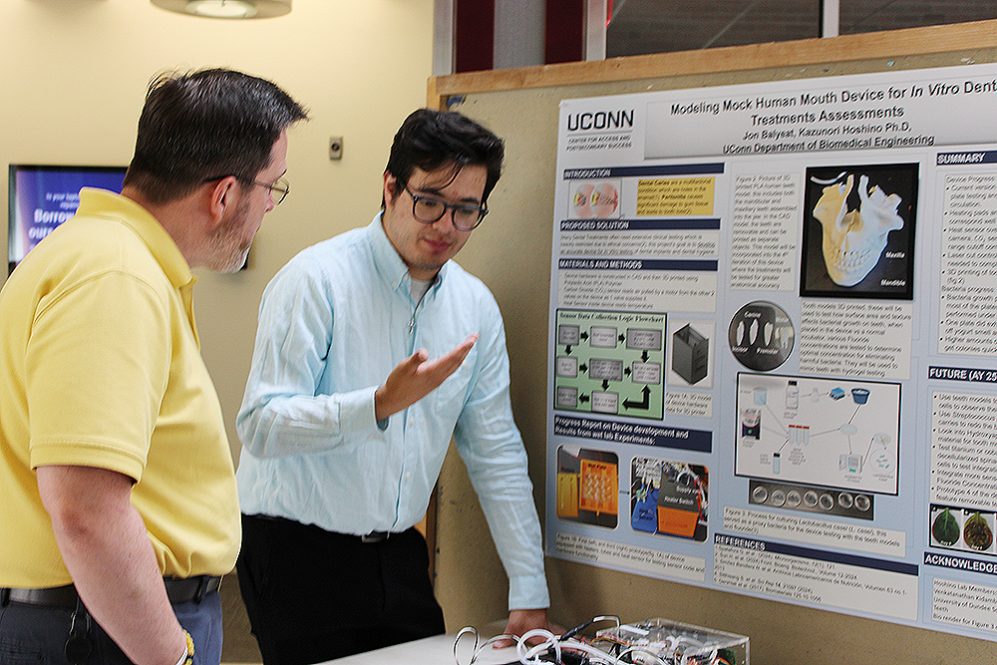

Balyeat presented his work during the CAPS Research Summer Poster Exhibit, held on July 23 in the atrium of the John Rowe Center for Undergraduate Education. CAPS Research opportunities advance educational equity by increasing access to higher education and transformative experiences that support retention and graduation for students who are first-generation to college, from low-income households, and from populations underrepresented in graduate education. Students begin as Scholars as second or third year students, advance research projects year-round until they graduate, and actively partake in community engagement with their Scholar peers to enhance their capital and be ready to thrive to and through graduate school.

“Jon is one of four CAPS Research Scholars and McNair Scholars this cohort from the College of Engineering. He embodies the spirit of our program mission – he’s intellectually curious, innovative, and deeply committed to using science to make a difference,” says Renée Trueman, director of the UConn McNair Scholars Program and CAPS Research Scholars Program. “It’s great to watch Jon gain perspective about what he wants to study within biomedical engineering in graduate school.”

Balyeat’s concentration is in biomaterials and tissue engineering in the College of Engineering. Specifically, he’s interested in regenerative medicine and implantable bioelectronics, bone tissue and neurons, and synthetic biology. He’s also fascinated with using algae to develop innovative solutions and products.

Balyeat and three other students participated in the U.S. Department of Energy’s second annual AlgaePrize competition last May. The team extracted polymers from seaweed to create an eco-friendly antimicrobial product that can be sprayed on produce. The spray extended the shelf life in strawberries and reduced the risk of bacterial infection.

Balyeat will travel to the University of New Mexico in September for an undergraduate research conference and present his project alongside McNair Scholars from across the nation.

“I plan to use many of the skills I learned from the competition in my future biomedical research as I aim to translate lab discoveries into practical solutions,” he says.

After graduating, Balyeat intends on applying for graduate school and ultimately pursuing a doctorate in biomedical engineering and founding his own lab. He also enjoys composing music, making 3D animations, and building intricate fictional worlds.

“I have many creative outlets that keep my problem-solving abilities fresh, logical and imaginative,” he says.