When it comes to the aerospace industry, PCX Aerostructures is in the big leagues.

The company is a premier supplier of advanced mechanical systems, specializing in both commercial and military rotorcraft markets, providing highly engineered precision machining of complex parts where tight tolerances and quality are imperative. PCX supplies major customers such as Bell Helicopter, Boeing, Sikorsky and the U.S. Government. It produces flight-critical components to the industry’s highest standards.

When PCX executives reached out to UConn to ask for advice on improving some of their critical data-collection systems—with the goal of developing quicker and more efficient access to data, and reducing expenses—UConn School of Business faculty members were eager to assist.

Six graduate students spent the spring semester helping the aerospace manufacturer strategize improvements in supply-chain management, inventory assessment, and labor-management efficiency.

Aris Fotos, PCX’s general manager and COO, said the assistance has been invaluable.

“In this highly competitive manufacturing sector, we’re always striving for continuous improvement in every facet of our business,” he said. “It’s critical that we seek new opportunities to help position ourselves as an industry leader. This certainly gives us an edge.”

A Proud, Thriving Yankee Company

Few companies can boast of the deep Connecticut roots that PCX Aerostructures can. The company was founded in 1900 by Wilson Fenn as a machine shop specializing in plug and ring gages and ultimately made a brand name for itself through metal-forming machinery. In the 1940s, thanks to a relationship with Sikorsky, the company delved into aerospace.

A community fixture since 1954, the Newington company continues to thrive. PCX doubled its business in the last two years and increased its labor force by 30 percent in the past 18 months. The company’s Connecticut headquarters employs 177, while an additional 63 are based at its sister company in Mansfield, Texas.

PCX also offers integrated special processing services such as heat treating, painting and non-destructive testing. It also possesses large mill-turn capacity and multi-axis gear shaping, in addition to precision gear manufacturing using state-of-the-art machinery.

“PCX is unique in the type of specialized machining and assembly capabilities that we possess. We rely on a skilled workforce to fill the need for Critical Safety Items that are integral, ‘zero failure’ components installed on an aircraft,” said Fotos who earned his MBA at UConn in 2000.

“It’s vital to engage our next generation of manufacturing talent,” Fotos continued. “Reaching out to partners like UConn helps us to leverage the knowledge and ingenuity of students who may be interested in aerospace as a career path.”

The company has invested $16 of new capital equipment in the last five years—a strong selling point for some of the industry’s largest names in aviation, who rely on manufacturers like PCX to embrace the latest technology while minimizing down time and seeking lead-time reductions.

As an industry leader, PCX attracts a wide range of talent, including CNC machinists, manufacturing engineers, programmers and quality inspectors, to name a few. The company attributes its ongoing success to the combined expertise inherent in its workforce.

“This shop is the only one in the world that makes certain parts for certain aircraft,” said Trevor Hartman, vice president of sales and marketing. “We’re a national asset.”

UConn’s Experts Love Data Challenges

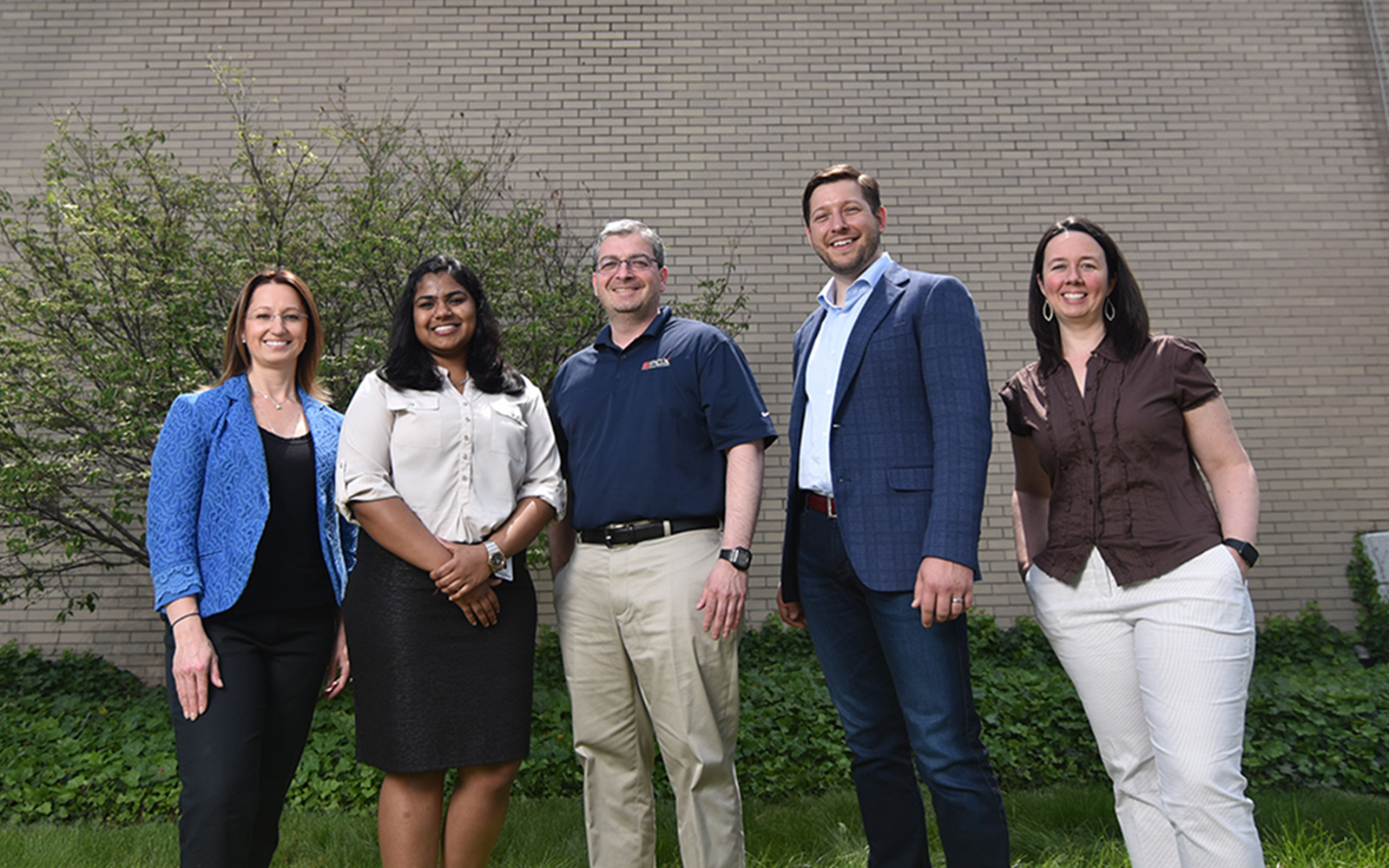

For Professor Jennifer Eigo, who heads the Center for the Advancement of Business Analytics (CABA) at UConn’s School of Business, this project was a perfect opportunity to help a Connecticut company and give students a chance to apply their analytical and project management skills.

“Strategic use of analytics can give a business the information it needs to make data-driven decisions, directly impacting its success,” Eigo said. “UConn is eager to help Connecticut businesses leverage analytics to stay competitive. Manufacturing is a big and important focus in Connecticut.”

“In addition to showcasing their analytics knowledge, our students gain a hands-on experience working with executive leadership,” said Professor Anna Radziwillowicz, who mentored students on the PCX projects. “They also learned more about how the manufacturing industry works and how they can apply value to the business. They gained an understanding of the end-to-end operations of a company in the manufacturing industry, through the lens of executive leaders.”

Students Quickly Immersed Themselves in the Company

Don Pendagast, a UConn MBA student, said the experience will be useful in his career as a management consultant.

“Coming into an organization that I was not at all familiar with, I had to quickly learn about the company, its challenges, and come up with solutions,” he said. “You have to understand the business behind the data.”

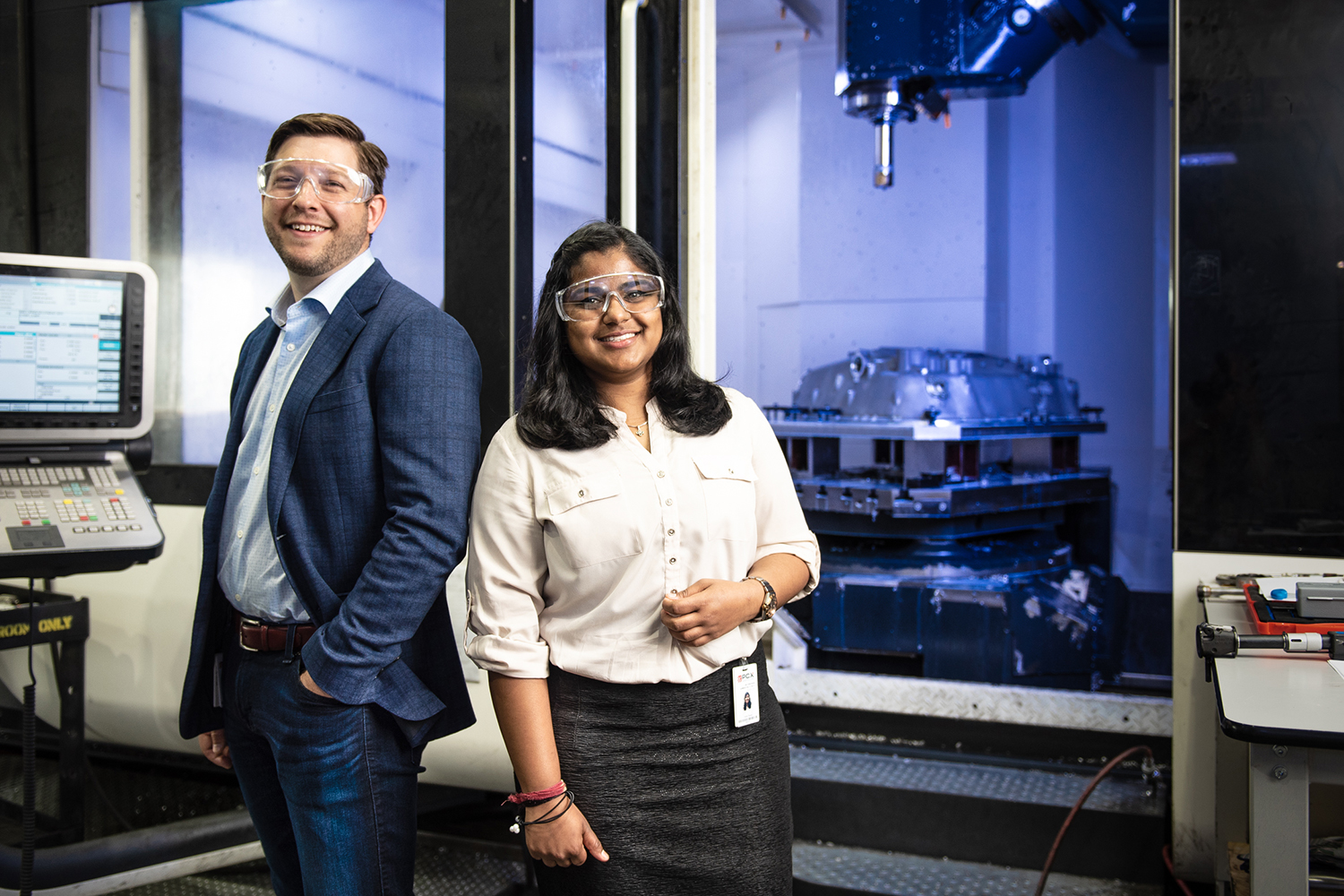

Chitra Reddy, a UConn graduate student studying business analytics and project management, described her work on labor-management analysis as phenomenal and exhilarating.

Like Pendagast, she had no manufacturing background. It was particularly rewarding, she said, to know that she contributed to the well-being of the company. As a future business analyst, interacting with the executives, understanding their perspectives on nurturing the business, grasping the data needs and delivering the project “all provided me with a platform to prep myself for setting my foot out in a new professional journey post-graduation,” she said. “I am ever grateful for this amazing opportunity.”

“The students were a very mature group,” Fotos said. “We would receive emails, sent in the wee hours of the night. They truly did a great job. They were determined and able to create something useful for us.”

Two of UConn’s graduate students are currently working at PCX to implement the new plans, and future collaboration between the two organizations is likely.

Now PCX leaders spend a fraction of the time they did in the past gathering data, and can devote more energy to strategic planning and growth, Fotos said.