UConn, the University of Massachusetts Lowell (UMass Lowell), and Georgia Institute of Technology (Georgia Tech) announced a collaboration to establish SHAP3D, a National Science Foundation (NSF) Industry-University Cooperative Research Center (IUCRC), to address emerging challenges of additive manufacturing, also commonly referred to as 3D printing.

IUCRCs bridge the gap between early academic research and commercial readiness, supporting use-inspired research leading to new knowledge, technological capabilities and downstream commercial applications of these technologies.

“This Center will address the grand challenges that prevent the entire 3D printing field from moving forward,” says Joey Mead, Distinguished University Professor and David and Frances Pernick Nanotechnology Professor in the Department of Plastics Engineering at UMass Lowell. Mead serves as the center director of the Center for Science of Heterogeneous Additive Printing of 3D Materials (SHAP3D).

“Our vision is to establish a synergistic national network of excellence in additive manufacturing knowledge, experience and facilities that will add value to the additive manufacturing industry, which is expected to top $20 billion within the next five years.”

The three universities, each serving as a site, are working cooperatively as SHAP3D, one of nearly 75 IUCRCs nationwide, to conduct pre-competitive research that will guide future technologies in 3D printing. The NSF funding supports the partnership, universities provide the research infrastructure and talent, and industry partners provide research funding and guide university researchers on industrially relevant projects. All members vote on the research areas the center should pursue, and research is conducted at university sites.

The NSF’s IUCRC program enables industrially-relevant, pre-competitive research via multi-member, sustained partnerships among industry, academe, and government. NSF supports the development and evolution of IUCRCs, providing a financial and procedural framework for membership and operations in addition to best practices learned over decades of fostering public-private partnerships that provide significant value to the nation, industry and university faculty and students. There are currently about 70 centers and over 800 unique members nationwide.

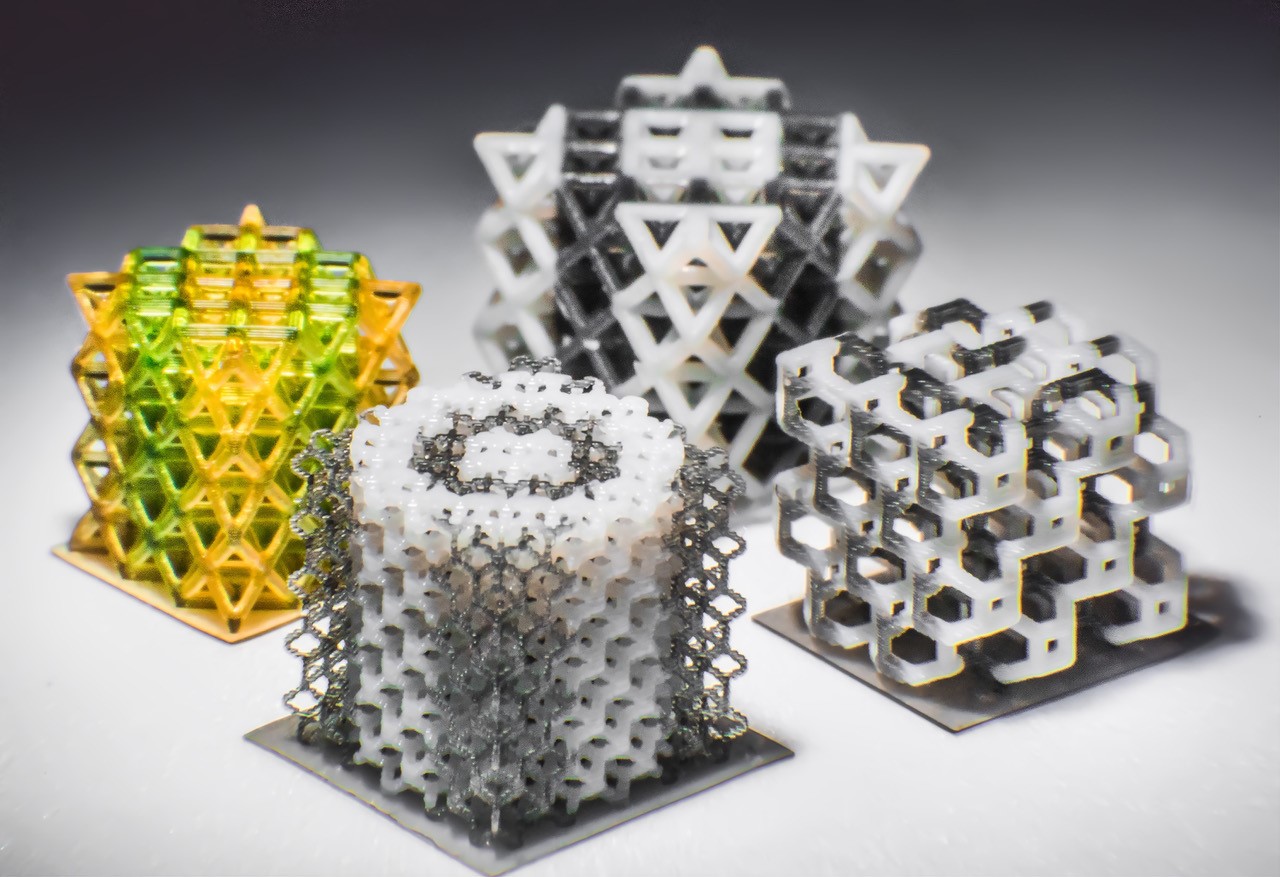

While the new joint center will cover many facets of 3D printing, from materials development and new printer design to modeling and applications, each site focuses on specific areas based on their strength and works collaboratively with other sites.

The UConn center site is primarily focused on 3D printing applications for aerospace, shipbuilding and biomedical applications since these industries all have a strong foothold in Connecticut. The UML site, based on its renowned plastic engineering program, focuses on developing new printing and processing methods as well as developing new polymer feedstocks for future 3D printing. Georgia Tech focuses on developing new functional materials and hybrid printing technologies and studying design methodology.

“We’re trying to set up an ecosystem where we can all work together to solve fundamental research questions that are both intellectually stimulating and technologically relevant to the additive manufacturing field,” says Anson Ma, an associate professor in UConn’s Department of Chemical and Biomedical Engineering and Polymer Program and the site director at UConn.

Rainer Hebert, an associate professor from the Department of Materials Science and Engineering, serves as the site co-director.

The IUCRC brings together large companies, small businesses, startups and government agencies in a collaborative research ecosystem.

“We’re trying to be as inclusive as possible because this is a relatively new field, and the research and development landscape is changing at amazing speed,” says Christopher Hansen, an associate professor in UML’s mechanical engineering department and the site director at UML.

Currently, 14 companies have committed to join the center, which will provide $2.25 million for SHAP3D to conduct precompetitive research.

“By working with industry partners, university researchers can focus on topics with great commercial potential and create more practical uses for 3D printing,” says H. Jerry Qi, the Georgia Tech site director and a professor at the George W. Woodruff School of Mechanical Engineering. “The center will also serve as a training ground for next-generation leaders in additive manufacturing and provide a talent pipeline to industry.”

“This new center is really exciting and we’re so glad NSF supports our vision and is willing to fund it,” says Mead. “The whole is larger than the sum of its parts, so we are looking forward to expanding this center to include more universities, industry partners and government agencies.”

Learn more about the IUCRC program at http://www.iucrc.org/.