A new company, created by a pair of UConn graduate students, is developing an innovative technique using sensors to monitor the performance of bridges. The Department of Transportation monitors key aspects of a bridge’s health to make sure they remain safe.

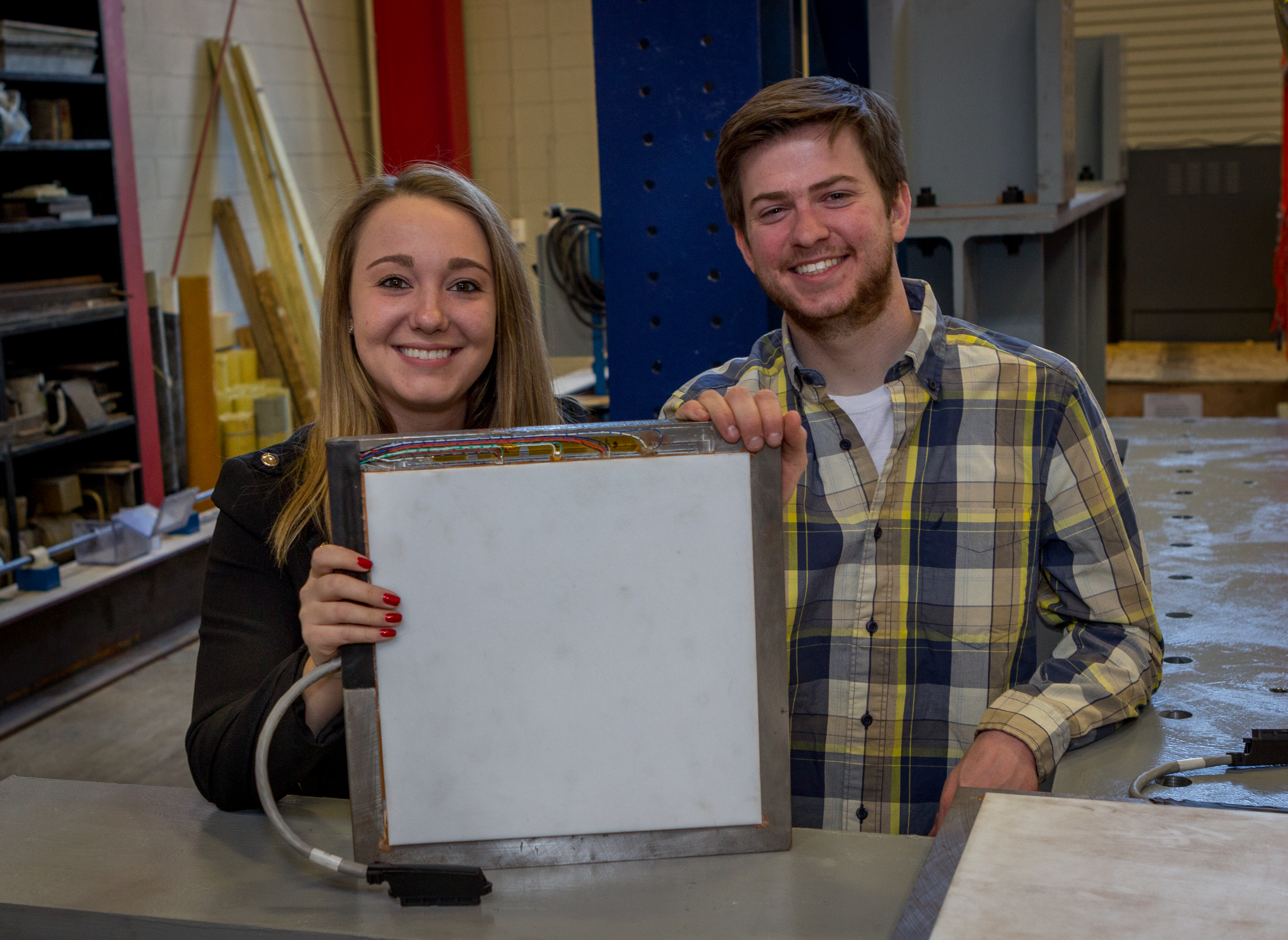

Civil engineering graduate students Kevin McMullen and Alexandra Hain are improving on the current methods for bridge monitoring, which are expensive and time consuming. McMullen’s company, NexGen Infrastructure, is developing force sensing pads which can be built into structural bridge bearings to perform the monitoring. NexGen Infrastructure received a Third Bridge Grant for financial support to develop a prototype and fine tune their product. McMullen said that the company’s force sensing pads can provide key data faster than current methods.

“One benefit is that you can determine if a bridge is over-stressed, if the weight is higher than it was designed for,” McMullen said.

By inserting NexGen’s sensors into the bridge infrastructure, McMullen and Hain are able to measure how well a bridge is performing over the lifetime of the sensors. This can include ensuring that a new bridge functions as intended, measuring how a bridge’s performance changes over time, and even weighing trucks that go over the bridge, which could make weigh stations unnecessary.

The sensors can be inserted during new construction or when a bridge is being repaired. Many of the bridges in the United States have reached or exceeded their expected life cycle. According to Hain, “Repairs are often done to these bridges to extend their life span. A perfect time to insert these pads is when the bearing is being replaced.”

NexGen Infrastructure grew out of an Experiential Tech Entrepreneurship Course that McMullen and Hain took, which encourages and develops the necessary skills for engineering grad students to become entrepreneurs and create startups. McMullen, along with Assistant Professor of Civil and Environmental Engineering Arash Zaghi, had done a research project with Enflo Corporation, which manufacturers Polytetrafluoroethylene (PTFE), a Teflon-like material used in bridge bearing pads. The sensor pads were created to improve the marketability of Enflo’s PTFE bearing pads.

During the entrepreneurship course, McMullen worked with Hain to develop the bridge pads. Zaghi, their faculty advisor, acts as the director of research development for the company.

Students who take the course are qualified to pitch for the Third Bridge Grant, a program that provides financial support for UConn startups from engineering graduate students. The Third Bridge Grant is a member of the UConn Entrepreneurship and Innovation Consortium.

McMullen is using the funding to work with industry partners to make the sensor pads as effective as possible. UConn Engineering Professor of Practice Hadi Bozorgmanesh teaches the entrepreneurship class, and he partnered with Connecticut Innovations to establish the Third Bridge Grants. He said that these programs are part of a concerted effort to turn engineers into entrepreneurs.

“We’re trying to get science and engineering students to convert their inventions into innovations that result in new products and services. We want them to understand the business world, and to think strategically with business goals in mind,” said Bozorgmanesh.

While working to develop NexGen into a viable company, Hain decided that she wanted to branch off and develop a separate company. Advanced Column Solutions develops durable, resilient and cost-effective alternatives to conventional bridge columns. A Third Bridge Grant has been awarded to the company which Hain will use to advance the development and marketability of the innovative column system.