Like most products that come from nature, rubber comes with a fixed shelf-life, causing consumers to spend money on replacements. Think car tires.

But recent research by the University of Connecticut and University of Southern California has resulted in a new type of “self-healing” rubber. The findings, published in the February issue of NPG Asia Materials, are inspired by the researcher’s fascination with how human and animal body tissue repairs itself.

“The idea of self-healing rubber actually comes from nature,” says Ying Li, engineering professor and co-author. “For many natural materials, such as our tissues, they can heal themselves without external intervention.”

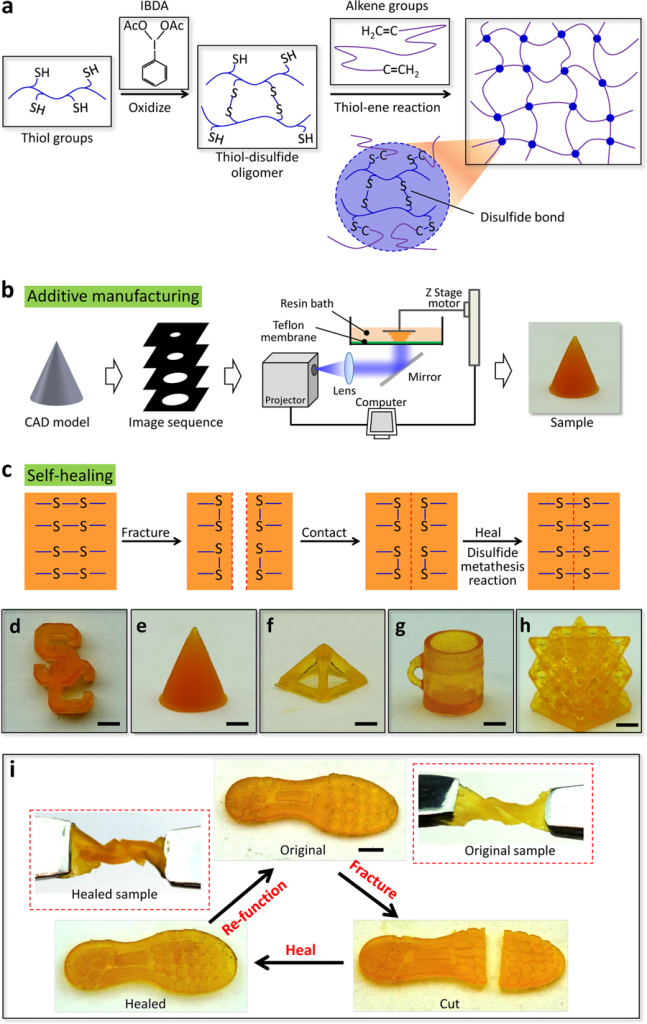

In nature, the disulfide (S–S) bond is a reversible cross-link that provides tunable stability to folded structures of proteins with specific mechanical functions, such as molecular sensing, switching and signaling. The researchers incorporated this disulfide bond into a polymer for self-healing capability, says Li.

Researchers then created the new product using a 3D printing method called photopolymerization. Photopolymerization is a technique that uses light (visible or ultraviolet) to initiate and promote a polymerization reaction to form a linear or cross-linked polymer structure. It is one of a few 3D printing techniques that can create complex 3D geometries.

Researchers then created the new product using a 3D printing method called photopolymerization. Photopolymerization is a technique that uses light (visible or ultraviolet) to initiate and promote a polymerization reaction to form a linear or cross-linked polymer structure. It is one of a few 3D printing techniques that can create complex 3D geometries.

That disulfide bond, created through the use of a molecular photoelastomer ink with both thiol and disulfide groups, was the key to creating the material using a 3D printer. Li said that while other researchers and companies have made self-healing rubber, this was the first successful attempt at creating a self-healing rubber material using 3D printing methods.

“The 3D printing is used to print these self-healing polymers into complex geometries, with many potential applications in the soft robotics, flexible electronics, and artificial organs. Essentially, we are 3D printing a new kind of rubber,” Li said. “There are some smart rubbers that can self-heal, after fracture, on the market. Unfortunately, these rubbers are not easily processed and cannot be 3D printed.”

In the study, Li and USC co-collaborators Qiming Wang, professor of engineering; An Xin and Haixu Du, graduate students, printed a wide range of objects in 3D.

The objects — including a shoe pad, an electronic sensor, and a soft robot — were all then cut in half. The researchers heated the objects to 140 degrees Fahrenheit for two hours. After heating the objects, they put them through several strength tests that proved not only was regeneration possible, but regeneration at nearly 100 percent strength.

Applications for this new type of rubber, Li says, are limitless.

“These 3D printable and self-healing rubber-like materials will have a big market in the future,” Li says. “They can be made into complex shapes for many different applications with the self-healing capability.”

This research was funded by the Air Force Office of Scientific Research Young Investigator Program (FA9550-18-1-0192) and the National Science Foundation (CMMI-1762567 and 1762661).