In response to a rapidly expanding commercial hemp industry driven by interest in products with CBD oil, the University of Connecticut recently opened a laboratory where the plant can be tested for a variety of compounds.

As part of the Center for Environmental Sciences and Engineering’s Hemp Initiative, the UConn facility will support the efforts of growers, manufacturers, and researchers, and educate students interested in entering the field.

A non-intoxicating marijuana extract, cannabidiol – commonly known as CBD – has made its way into products treating everything from anxiety to seizures to pain. This fall marks the culmination of the state’s first growing season since federal legislation to legally grow and harvest the hemp crop, which produces the oil.

After last year’s passage of the Farm Bill, many Connecticut growers invested in new economic opportunities with hemp agriculture.

Hemp, a fiber of the cannabis plant, is considered marijuana if the level of a principal active chemical is above a specific percentage. But tetrahydrocannabinol (THC) levels can vary among individual plants, and even within the same plant, depending on the genetics and conditions in which the plant is grown.

Therefore to comply with federal regulations, licensed growers are required to have the THC level tested on the crop pre-harvest. The process requires growers to take samples from a number of plants within a crop and have them tested.

“As a producer, you want to ensure that you are not only legal but also that your product is safe and has the level of CBD compounds you hope will be promoting the health of those who are using the products,” says Michael Willig, executive director of the Institute of the Environment and Center for Environmental Sciences and Engineering.

“Consumers want to know that what is on the label is what they are taking, and that this information is consistent,” he adds.

When THC levels are below or equal to 0.3%, the plant is simply considered hemp. Above that level, the plant is considered marijuana, which is still recognized as a drug by the United States Drug Enforcement Administration.

The labs in the Center for Environmental Sciences and Engineering have been a resource for accurate and non-biased environmental testing for years, says Willig, so it seemed natural that the lab could also accommodate the needs of the state’s growing hemp industry.

While there are privately owned labs performing the same testing in the state, the Center for Environmental Sciences and Engineering is the only university lab currently seeking accreditation for the analysis of hemp and hemp-derived products in the United States. The accrediting body, the International Standards Organization (ISO), has stringent testing, record keeping, and traceability standards.

Since it opened in mid-September, the facility has already begun testing samples from over 25 growers state-wide, roughly one-third of the licensed farms in the state.

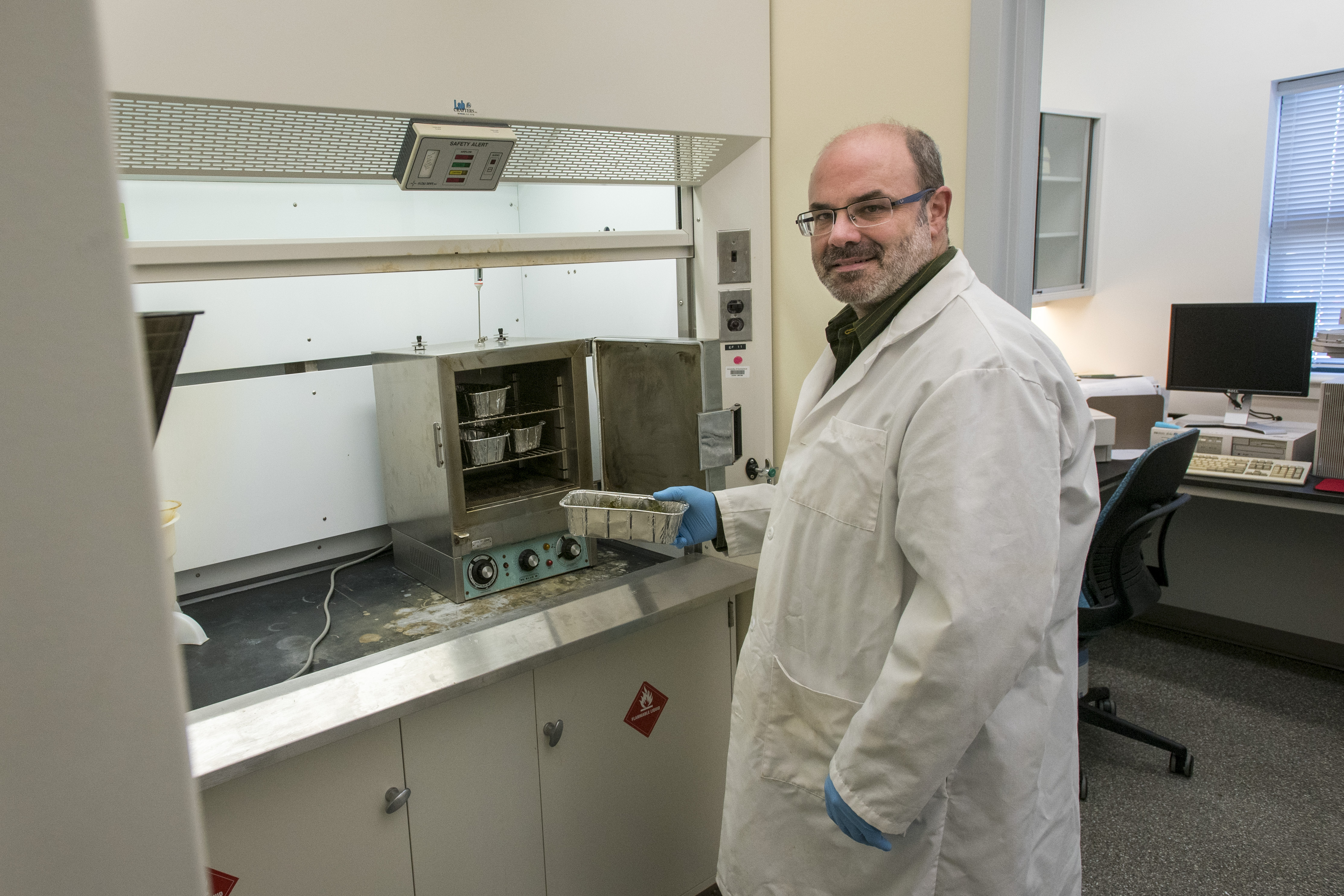

“We have received samples largely due to word of mouth as well as by referrals from UConn Extension educators,” says Christopher Perkins ’89 (CAHNR) ’95 MS, Center for Environmental Sciences and Engineering laboratory director.

The rapid growth of the lab’s client base indicates the demand for testing facilities, and the university’s dedication to supporting economic growth in the state. There is only one other state testing facility in Connecticut, located at the Connecticut Agricultural Experiment Station, which tests for THC.

In the near future, the UConn lab will be able to also provide analyses of samples post-processing, which requires quantification of a more comprehensive suite of chemicals including pesticides, terpenes, metals, and microbes. That capability is expected to be in place by mid-November, says Perkins.

Beyond supporting the needs of the local agricultural industry, the new testing facility is providing valuable training to UConn students, to prepare graduates for roles in this rapidly growing field. In addition to medical products, the hemp plant also produces fiber for fabrics and building materials.

“We have amazing students who are highly qualified but not necessarily in all aspects of the hemp business. The quality control and quality assurance testing this lab performs and teaches are not skills typically taught at a university,” says Willig.

“This facility hopes to expand to include a dedicated teaching facility that will educate the next generation of professionals for managing and running labs like this in the public or private sector.”