The UConn Husky is a familiar mark on everything from t-shirts and sweatshirts to cornhole boards and cufflinks.

Now, add hand sanitizer to the mix; but this is not for sale at a favorite website. It is a handmade product by UConn employees and graduate students that is being donated to local facilities and charities as part of the effort to combat the COVID-19 pandemic.

The concept belongs to the Fraunhofer USA Center for Energy Innovation, located in the Innovation Partnership Building at UConn Tech Park. Chemical engineering doctoral student Noah Ferguson is the lead on the project.

“It was a couple of weeks into the pandemic, and we were having our weekly research group meeting,” says Ferguson. “We were bouncing ideas around of what we could do, and producing our own hand sanitizer came up. We all wanted to use our engineering skills to help the community.”

Ferguson and his team use World Health Organization (WHO) specifications to produce the hand sanitizer, making it in five-gallon batches.

“We have to have a certain concentration of alcohol and that depends on what kind you are using – either isopropyl or ethyl,” says Ferguson. “We have to put in hydrogen peroxide, which is used to sterilize the inside of the container, and then we add distilled water and a little bit of glycerin to keep hands a little bit moisturized so they don’t get totally dried out.”

Once the hand sanitizer is put in a bottle, it has to sit for three days to allow the hydrogen peroxide to kill any hearty microbes that still may be inside the container or in the solution. Ferguson said this mix was originally devised by WHO for developing nations where perfectly pure distilled water may be hard to come by.

The UConn team sticks to the exact specifications of the WHO formula, and don’t put in any additives like scents, as some makers do, due to allergy concerns.

“We are a good place to do this because we have the mixing and volume measuring apparatuses to make sure we are getting exactly the right proportions,” says Ferguson.

With the help Chris Larosa of the School of Engineering communications office and the UConn Purchasing Department, a label was developed featuring the “UConn Nation” logo that has become familiar during the pandemic, which says “Physically Distant, Socially and Globally Connected.”

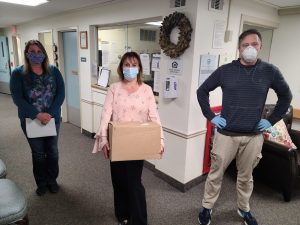

So far, about 1,400 two-ounce bottles have been distributed to senior living facilities in Mansfield, and to the Covenant Soup Kitchen in Willimantic.

The biggest challenges right now are getting the empty bottles to put the hand sanitizer in, and keeping a ready supply of ingredients for the sanitizer on hand, Ferguson says.

“The goal right now is to get to 20,000 bottles distributed and to do that, we need a robust supply chain of all materials, bottles, labels and chemicals,” says Jeffrey McCutcheon, an associate professor of chemical and biomolecular engineering and the executive director of the Fraunhofer Center.

Donations have come in from all over Connecticut on the project from companies and non-profits, including Parker Medical, Inc. of Bridgewater; Litchfield Distillery of Litchfield; Hubbard-Hall, Inc., of Waterbury; and Future Frogmen, Inc. of Westport.

“We have a good graduate student core team that has offered to come out and volunteer with the process,” says McCutcheon. “We haven’t needed them to a great extent yet, because Noah has done it all with Mayur Ostwal, who is a research assistant professor in our lab.”

“If we can make bottles in the 20,000 number, we can reach out a broader range of charities,” says McCutcheon. “We can work with food banks, first responders, and other communities of need. I began to get more confident in our ability as we crossed different thresholds…100 bottles, 500 bottles, and more.”

****

McCutcheon also gave an update on the emergency ventilator prototype that the Fraunhofer Center developed. Whitcraft, Inc., an aerospace manufacturer supplier located in Eastford, produced a ventilator based on UConn’s specifications, design and testing.

“We are going to send the ventilator to UConn Health so they can evaluate the performance,” said McCutcheon. “We will wait and see. The desperate need for ventilators is not there, but they are still interested. I think everyone should be interested in having something like this in their back pocket in case something happens.”