By: Eli Freund, Editorial Communications Manager, UConn School of Engineering

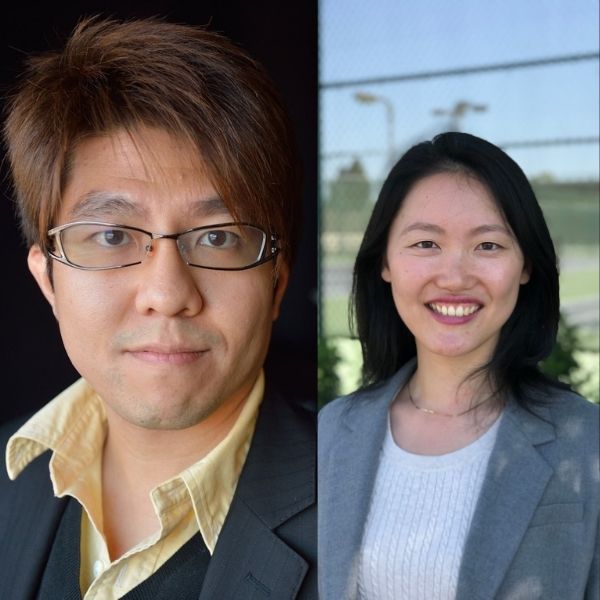

Armed with a four-year, $470,000 grant from USDA’s National Institute of Food and Agriculture, National Science Foundation (NSF) SHAP3D Center Site Director and Associate Professor of Chemical Engineering and Polymers Anson Ma—and his collaborator, Qian Yang, Assistant Professor of Computer Science and Engineering—are working on creating pulse-based food products with novel textures and customized nutritional profiles using machine learning and a specially designed 3D printer.

Pulses, which encompass all edible seeds in the legume family—including chickpeas, dry beans, lentils, and more—are seen as viable nutritional sources, as they are high in protein, complex carbohydrates, and low in calories and fat. During the next four years, the two researchers will work in conjunction with the U.S. Army Combat Capabilities Development Command Soldier Center (Natick, MA) to test their methods and results.

Ma and Yang will use UConn’s state-of-the-art pilot scale HuskyJet 3D printer housed at UConn’s Innovation Partnership Building. The versatile printer has a number of applications, which range from regular graphics on paper, to creating flexible electronics, medicinal tablets, and green parts for ceramics and metals. The printer was funded by UConn’s Academic Plan and has already been leveraged for a number of projects, including projects funded by the NSF SHAP3D center and a federally funded project from NextFlex – America’s Flexible Hybrid Electronics Manufacturing Innovation Institute – both of which UConn is a founding academic member.

CCDC-Soldier Center will provide expertise in food 3D printing and nutritional solutions. Food is unlike other material used in 3DP, it is a uniquely complex non-linear material. CCDC-Soldier Center maintains 3D food prints with the capabilities and knowledge to characterize food matrices, conduct shelf-stability testing, evaluate sensory characteristics and perform nutritional and food microbiological analysis.

A number of societal benefits will be realized through this project. First, the ability to produce food that will meet an individual’s energy and nutrient needs, as well as flavor and texture preferences, and will help promote a healthier lifestyle. Second, by making the 3D printing technology more accessible, consumers will be able to experiment with different food forms at home, fostering creativity in the younger generations and changing their relationships with pulse-based products. Third, 3D food printers can function as standalone food production systems that could be used in disaster relief situations and austere environments. Lastly, the 3D food printing technology developed in this project can potentially be adapted for using a wide variety of sustainable feedstock materials.

For more information on Ma, and his research, please click here.

This research was funded by USDA grant #2020-67017-31273