What if we thought about our bodies as materials?

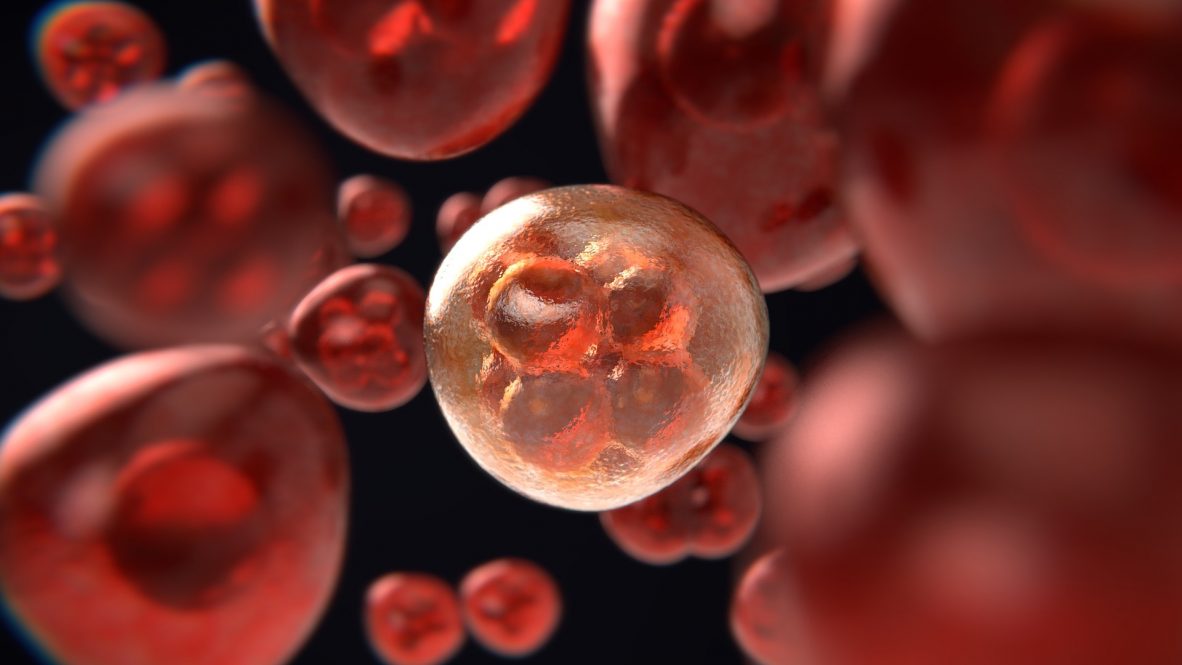

This is the question Associate Professor Kazunori Hoshino in the Department of Biomedical Engineering raises in analyzing three-dimensional (3-D) tumor models to test potential cancer drugs.

This technology will help bridge the gap between in-vitro – or petri dish – testing and human subject testing for cancer drug development while cutting out the need for animal models by applying engineering methods to medical research.

Currently, cancer drugs are first tested on two-dimensional monolayers of cell cultures. While this is a necessary step in testing drugs, many drugs that are successful at this stage fail when they get to more advanced animal or human trials.

Next, scientists graft human tumor cells onto animal models. This allows them to see how the drug interacts with healthy cells as well as the tumor. However, it comes with its own set of challenges, including cost, time, and ethical considerations.

To address these issues, Hoshino’s approach uses a 3-D model of a tumor in-vitro that can show how drugs will act in-vivo without the need of animal models.

“Testing an in–vitro model that mimics a tumor, rather than using animal models, is a recent trend in cancer studies,” Hoshino says. “However, the question to me was: can we create a proper analytical method to study such a model?”

Hoshino’s method uses materials science concepts to test the tumor like a material. Specifically, he tests for stiffness, or elasticity, a commonly tested property in engineered materials.

“If you’re creating a new material, you need to know the properties,” Hoshino says.

Hoshino hypothesizes that tumors will have different levels of stiffness. Scientists do know tumors have different properties from healthy tissue — often being significantly stiffer, for instance.

One possible reason for this stiffness is increased collagen production in tumors. They suspect this stiffness may protect the tumor by preventing drugs from reaching it.

Hoshino’s method uses a series of polymer “chopsticks.” These chopsticks have a specific, known stiffness, designated by number. If they bend, it indicates the tumor is stiffer than that number.

Users can choose a specific type of chopstick design and material to achieve a precise measure of the tumor’s stiffness. Hoshino’s group has created a variety of chopsticks that can be used for this purpose, and the latest example of using such a device for an in-vitro model has been recently published in PLOS One.

Another step is the detailed image analysis that visualizes the stiff and soft areas in the sample.

This “mapping of stiffness” will help researchers answer two critical questions for this kind of drug: how will it reach the cancerous cells, and can it do so without damaging healthy cells?

“First of all, the drug molecule has to reach the tumor,” Hoshino says.

Hoshino’s materials-based approach represents a novel way of testing cancer drugs. This method could also create significant cost savings for labs by reducing or eliminating the need for animal testing.

While this method alone may not definitively predict if a drug will work, it adds a valuable type of data to inform precision medicine approaches to treatment.

Hoshino is collaborating with experts in precision medicine at Weill Cornell Medicine to develop and test his technology.

“If we add mechanical testing to that, we can add new engineering methods to what they’re already doing,” Hoshino says.

Hoshino says he would eventually like his technology to incorporate other parameters that could better predict what treatment will be the most effective for an individual patient.

The development of this technology was supported through funding from the National Science Foundation #1942518 and #1809047.

The UConn Department of Biomedical Engineering is a shared department with the UConn School of Engineering, School of Dental Medicine, and School of Medicine.

Hoshino holds a Ph.D. in mechanical engineering from the University of Tokyo. His research focuses on nano and micro electromechanical systems, microfluidic systems for disease detection and analysis, nano and micro scale mechanical sensing and optical imaging, and microscale robotics for tissue engineering.

UConn Technology Commercialization Services has filed patent protection for this technology. TCS is looking for collaborators/licensees in the industry to move this technology forward. For further information, please contact Amit Kumar at techcomm@uconn.edu.