The Advanced Continuously Operating Reference Network (ACORN) has been supporting the work of Connecticut residents and the Connecticut Department of Transportation (CTDOT) for nearly a decade.

ACORN is a system that integrates high-end GPS receivers, operated by CTDOT, with servers run by the Department of Natural Resources and the Environment (NRE) at UConn to host real-time corrections to GPS surveyors and mappers. Fundamentally, ACORN users can produce centimeter-accuracy positions in real time, which opens up a host of applications and efficiencies not otherwise possible.

ACORN, which is free and available to the public, harnesses the power of GPS to make DOT surveys and inspections more time and cost effective. It also helps make construction sites safer for the workers.

Private surveyors and mappers use ACORN for daily work including property surveys, construction surveys, airborne mapping, and hydrographic mapping.

“ACORN is a system that allows GPS units of the proper type to have centimeters of accuracy in real time,” Thomas Meyer, professor of NRE, says.

ACORN uses a type of technology known as Real Time Kinematic (RTK) positioning. RTK allows the user to collect survey-accuracy data and see the results often in only a couple seconds. The alternative is to download the data at the end of the day into post-processing software, which is less efficient.

One application for CTDOT is that ACORN helps them conduct inspections of their construction projects.

When engineers design a bridge for the state, they include check points. Checkpoints are metal caps or nails that should be located at particular places on or around the bridge. Once the bridge is constructed, inspectors survey these checkpoints to verify whether they are where they are supposed to be. This tells them the construction crew followed the blueprints carefully and the bridge is safe for the traveling public.

Before the advent of ACORN in 2014, inspectors would perform inspections using conventional surveying methods, which were more time consuming and required a larger field crew. This could involving closing the bridge for hours or working late at night.

“It could be dangerous, expensive, and it was less effective than using RTK,” Meyer says.

Now, the inspectors load the blueprints onto a laptop mounted on a range pole that they take into the construction site. There is a GPS on top of the range pole that communicates with ACORN. The GPS provides the laptop with, typically, centimeter-accuracy positions in real time. The laptop displays the blueprints with the GPS shown in the middle, so inspectors see themselves walking around the blueprints as they move around the construction site. The inspector plants the range pole on each check point, surveys it with the GPS, and verifies that the check point was located where it was supposed to be.

The laptop does the record-keeping, so the process is fast, efficient, and less error-prone.

This process is an estimated 10 times faster and has saved the state around $500,000 annually.

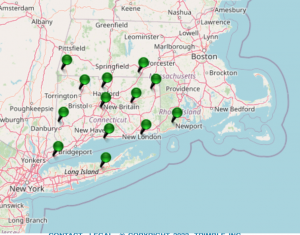

ACORN currently has nine sensors around the state, one in Rhode Island, two in southern Massachusetts, and one on Long Island, New York.

“It’s a fabulous example of collaboration between the university and the state,” Meyer says. “We have a fantastic relationship with our partners in the DOT.”

Having successfully completed an extensive testing and validation period, the State of Connecticut is now supporting ACORN with a line-item in the Department of Transportation’s budget, ensuring ACORN is able to continue supporting these vital functions.