UConn Technology Commercialization Services (TCS) is working with the Connecticut Agricultural Experiment Station, New Haven (CAES) to commercialize a technology that makes spent emissions of a greenhouse gas fumigant safe to release into the atmosphere.

UConn TCS is working to support Connecticut’s entrepreneurial ecosystem beyond the University, by helping non-UConn researchers, like those at CAES, commercialize their intellectual property.

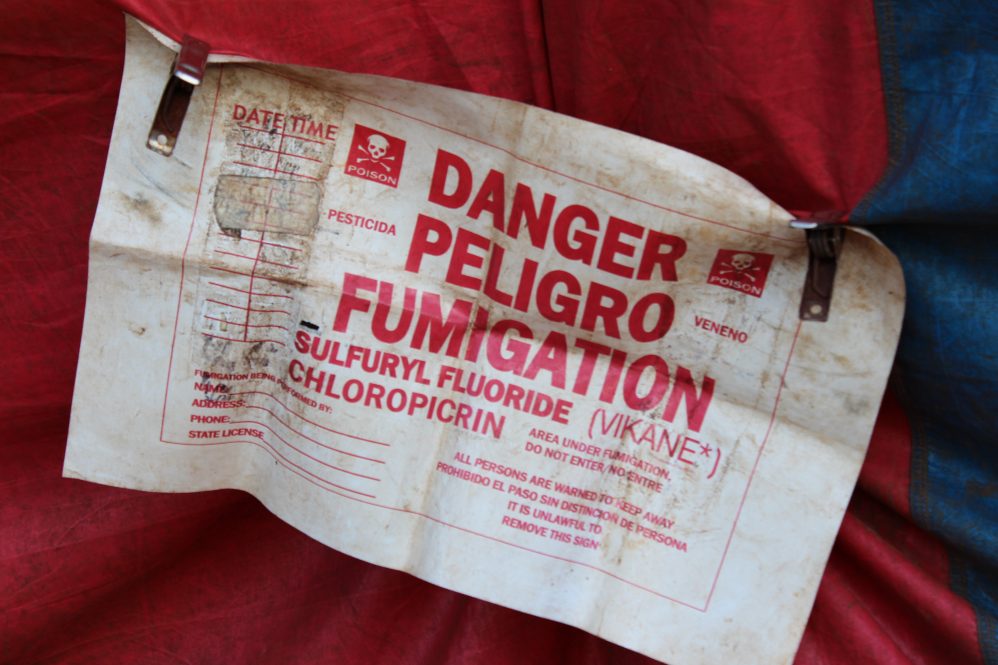

Sulfuryl fluoride is a common fumigant used to treat insect infestations in buildings and, increasingly, produce, lumber, and other internationally shipped products that could be carrying invasive pests.

Sulfuryl fluoride was originally touted as an alternative to methyl bromide, an ozone-depleting gas. Methyl bromide was previously the standard fumigant for international shipments.

“It was hailed as a great replacement for methyl bromide because it was quite effective and it wasn’t an ozone depleting gas,” Joe Pignatello, distinguished chief scientist emeritus at CAES, says.

However, scientists have found that sulfuryl fluoride is a greenhouse gas. Sulfuryl fluoride has a global warming potential (GWP) of 4780, compared to carbon dioxide, which has a GWP of one. GWP is a measure of how much infrared thermal radiation a greenhouse gas added to the atmosphere would absorb over a given time frame, in this case 100 years.

When sulfuryl fluoride is used to fumigate imports, it is pumped into a large shipping container. The sulfuryl fluoride remains in the fumigation chamber for hours and then fans blow it out into the atmosphere.

Working on a U.S. Department of Agriculture-funded project, Pignatello developed a technology that can clean sulfuryl fluoride fumes before they are released into the atmosphere.

Rather than immediately releasing the gas into the atmosphere, with Pignatello’s technology, the gas would first pass through a tube into a “spray scrubber.”

The spray scrubber is a tank filled with liquid. The scrubber creates a mist which mixes with the incoming gas stream containing the sulfuryl fluoride. The mist droplets have a special chemical makeup that allows them to react with sulfuryl fluoride which cleanses the gas stream.

“Our method involves a unique combination of reagents that are put into the liquid of the tank and react rapidly with sulfuryl fluoride,” Pignatello says.

Then, once the gas is “cleaned” it can be safely ventilated into the atmosphere.

The wastewater can easily be treated to make it safe to dispose. The scrubbing process creates fluoride, which can be transformed into an insoluble, harmless compound – calcium fluoride – and sulfate, which naturally occurs in fresh and sea water.

“I think the future looks pretty good for this technology,” Pignatello. “Because fumigators are going to have to find a way to prevent spent fumes from going into the atmosphere.”

UConn TCS has assisted CAES in establishing an exclusive option agreement with a private company to commercialize this patent-pending technology.

This partnership, facilitated by TCS, serves as the first of hopefully more such commercialization engagements the UConn office will facilitate for its external research partners.

“This is just one of many ways that UConn is growing the innovation ecosystem in Connecticut and beyond,” Christopher Conners, TCS licensing director for life sciences, says.