The Wave Engineering for eXtreme and Intelligent maTErials (We-Xite) lab, led by engineering assistant professor Osama R. Bilal, has developed a reconfigurable metamaterial that can control sound waves – bending them, dampening them, or focusing them – while encoding real-time tuning with almost infinite possible shapes.

Their work is now published in the journal Proceedings of the National Academy of Sciences (PNAS).

“Metamaterials are artificial materials that can achieve extraordinary properties not easily found in nature,” explains Ph.D. candidate Melanie Keogh ‘22 (ENG), the first author of the study. In this case, the research team wanted to develop a material that could control sound waves, while being adjustable in both frequency and function, with potential applications ranging from medical imaging to soundproofing.

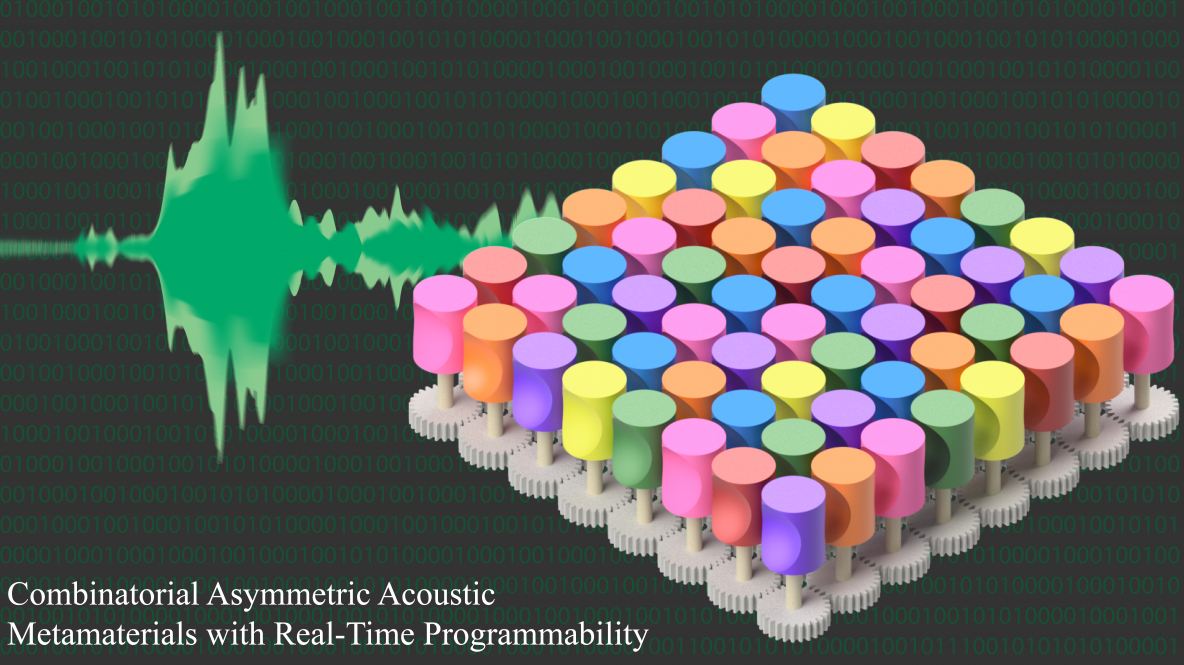

The metamaterial is made up of asymmetrical pillars with one or more concave faces – sort of shaped like an apple core. These pillars are arranged in an 11×11 grid, with motors controlling the orientation of each pillar. The motors are finely tuned, allowing the orientation to be controlled in one-degree rotation increments.

Sound waves, when beamed through the material, bounce off the concavities of the pillars. And because each pillar can be individually adjusted, there are an almost infinite number of potential paths that can be created for the sound waves to travel through the grid.

This means that the material can be used to intensify the effect of sound waves by beaming them to a single point. Such applications are highly useful in acoustic tweezers, medical imaging techniques such as ultrasound, or in targeted therapeutic techniques.

“Imagine something like a brain tumor – something you want to destroy, but at the same time, you can’t go in there with a scalpel. You can’t even go in there with very high-intensity sound, at the beginning,” explains Bilal. “So you need to have very low-amplitude waves that will focus only on a single point, and after that will disperse. In that way you can weaken a tumor, or attack a kidney stone, or you can manipulate small particles inside the human body that you can’t really access – but sound waves can.”

Conversely, the developed metamaterial can also be used as a platform for studying fundamental concepts in waves physics. One example is topological insulators, or materials that can conduct electricity along their boundaries but not through their core — a concept which received the Nobel Prize in Physics a few years ago. The research team used their metamaterials to control sound in a similar way, meaning that the sound waves can be directed to travel along the outside of the material without penetrating it.

In another study, the team is using metamaterials to reduce drag forces on moving objects, reducing energy and fuel consumption.

“This is a big deal for our field, because usually you can have a handful of stable states that you can tune your material to, but this one here gives us more configurations than the number of atoms in the universe,” says Bilal. “That’s how significant this is for our community.”

Keogh explains that the research team got the idea to use gears or motors to turn the individual pillars because they wanted to solve a persistent engineering problem: “Traditionally, metamaterials are fixed, meaning that they can’t change shape after being manufactured.” For a metamaterial that manipulates sound, this would mean that it could only be “tuned” to control a specific frequency range – not very versatile. A fixed metamaterial may also become completely ineffective if it is damaged, even by regular wear and tear.

In contrast, this metamaterial “allows you to reorient it or ‘tune’ it without manufacturing the whole material again,” says Keogh.

And because the motors can be electronically controlled, they make it easier to program the material in real time, over and over, instead of resorting to re-manufacturing.

“One additional thing that is unique about this paper is the combinatorial aspect,” Keogh elaborates, demonstrating that the effects of the metamaterial can be controlled even further by orienting pillars in combination with one another. Two, four, or more pillars moving together constitute a “supercell,” which offers even more variables for engineers to play with.

“We can play a lot of tricks with this platform,” says Bilal. “Supercells combined with asymmetry help us expand the design space even further. This is a very versatile approach to tuning metamaterials.”

The immense scope of the design space poses challenges — with so many potential configurations of the pillars, it would be impossible to manually calculate how each one would affect sound waves. Keogh jokes that if she began the work now, her grandchildren would still be working on the calculations.

Bilal poses the question this way: “If you have to navigate the number of atoms in the universe, which one do you pick?”

The research team is turning to AI algorithms and heuristics to help understand how the material will propagate sound across various configurations. “The end goal will be a fully autonomous material that has both the ability and intelligence to optimize its performance through machine learning,” says Bilal. “This material platform brings us a step closer to reach our lab vision of wave engineering through extreme and intelligent materials.”

A Journey Years in the Making

Keogh and Bilal’s journey of collaboration began when Keogh was an undergraduate, when she took Bilal’s course on vibrations. She began doing research in Bilal’s “We-Xite” lab, coming highly recommended by a fellow professor.

Keogh says she was initially interested in going into industry after she graduated. But through the course of her undergraduate research experience, she realized that work in the lab is often “years ahead” of the solutions being implemented in industry.

“I like being on the cutting edge,” she says.

“For many years now in our lab, we’ve been trying to program materials to have a certain function, but we’ve always been limited by the number of possibilities we can have,” says Bilal. “When I started this project with Melanie, I told her, there is a limitation on the number of motors we can control. What happened was, Melanie, who is so good with electronics … She just sat down in the lab and built all the circuitry for this platform. This is a very big project – you need to stack the pillars in a very specific, very precise way, and you need to control every single one of them. She did it, in the most wonderful way you could think of.”

“In my mind, this is what UConn is all about,” he adds. “Training young engineers to grow and mature into professional, world-class scientists is one of the most rewarding parts of being a professor.”