The University of Connecticut, working with the United States Economic Development Administration and Connecticut Innovations, is creating a center to share computer modeling facilities and related expertise with small and medium-sized Connecticut manufacturers, to help these companies create products faster and more efficiently.

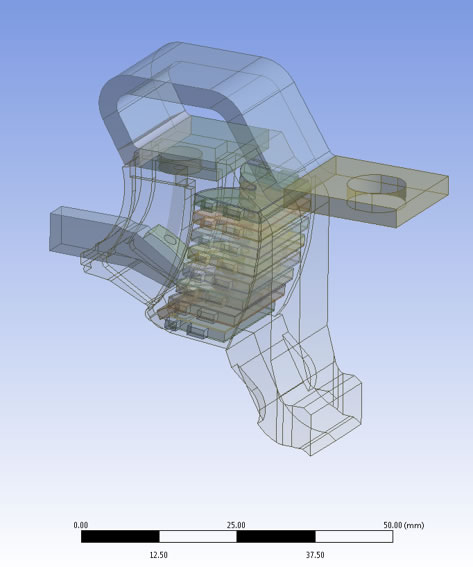

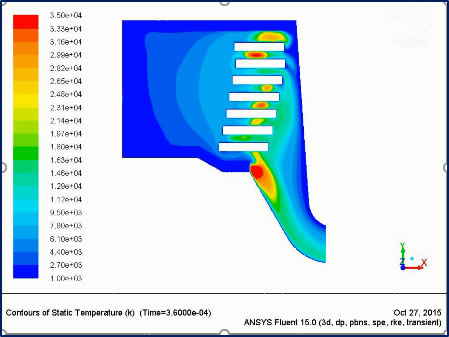

A $2.1 million combined investment over five years will create the Connecticut Manufacturing Simulation Center, or CMSC, which will give small and medium-sized Connecticut companies access to resources for computational design, modeling, and simulation, as well as high-performance computing hardware. By using computer models to test and modify new product designs and manufacturing processes virtually before making a physical prototype, almost all manufacturing companies can lower their design and manufacturing costs.

“The Connecticut Manufacturing Simulation Center will allow UConn to share our advanced modeling capabilities with industry throughout the state,” says Kazem Kazerounian, dean of the UConn School of Engineering. “These simulations can dramatically decrease the time and money needed to bring new technologies to the market, allowing manufacturers to create new products more efficiently and contribute more to the state’s economy.”

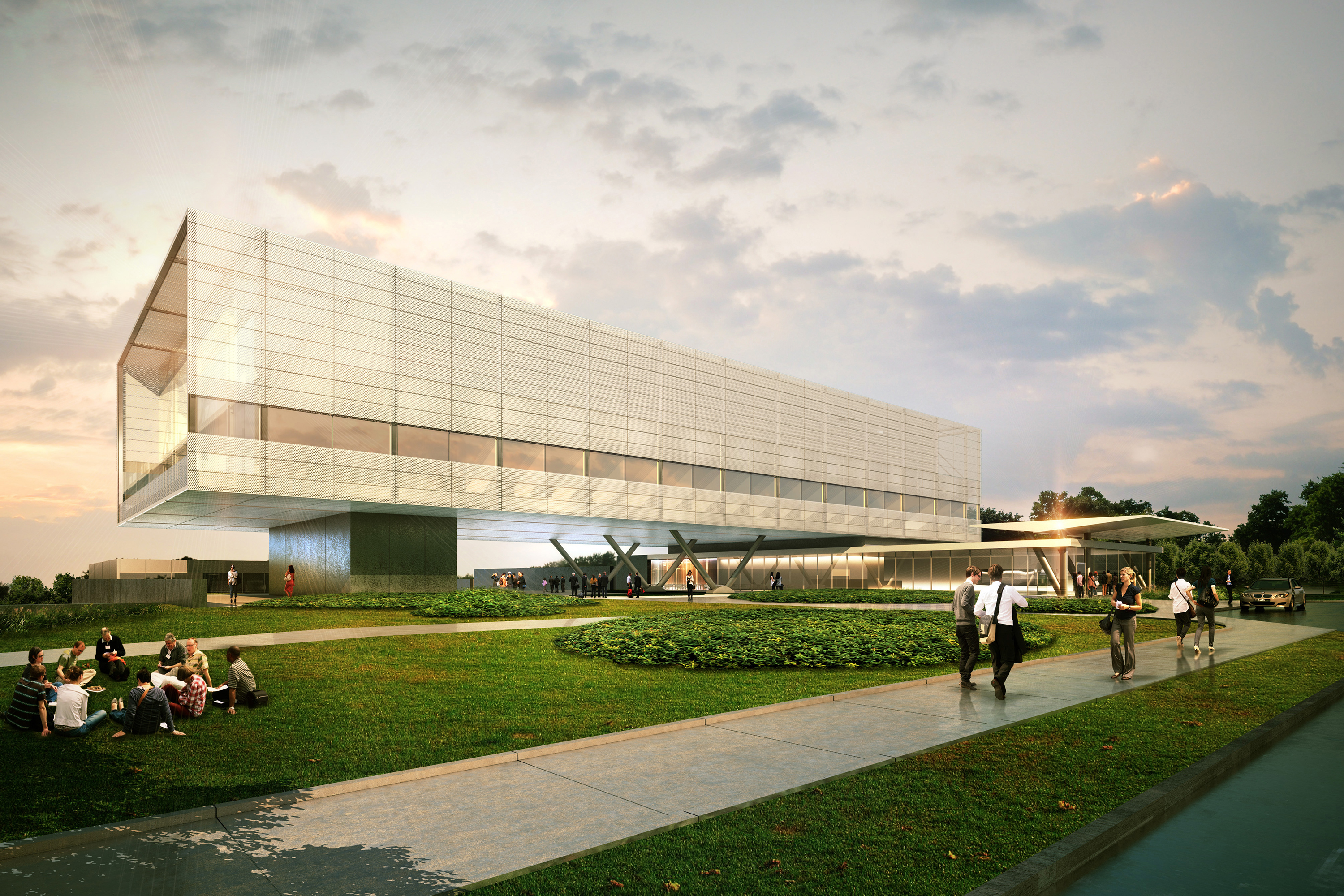

The CMSC will work on a subscription model, giving businesses access to modeling technology for a fraction of the cost of installing a similar high-performance computing system. The CMSC will be housed within UConn’s new Tech Park, with the first building scheduled for completion next year.

In addition to the modeling capabilities, the CMSC will create a workforce pipeline of students and professionals trained to use these resources. UConn will work with Connecticut’s community colleges and the Advanced Manufacturing Centers to ensure there are enough trained and capable workers to meet the state’s workforce needs.

“At the earliest stages of company development, efficiency is integral to success,” said Matt McCooe, CEO of Connecticut Innovations. “This center provides manufacturers with UConn’s expertise, which can have a direct impact on their bottom line.”

Hadi Bozorgmanesh, director of the UConn Entrepreneurship and Innovation Consortium, emphasized the potential to create new jobs.

“Eighty percent of Connecticut manufacturers that could benefit from high-performance computing in their product development or manufacturing are not doing so,” said Bozorgmanesh. “By providing a pipeline of trained employees and access to high-level modeling technology, we’re hoping to create over 700 new jobs in the next five years.”