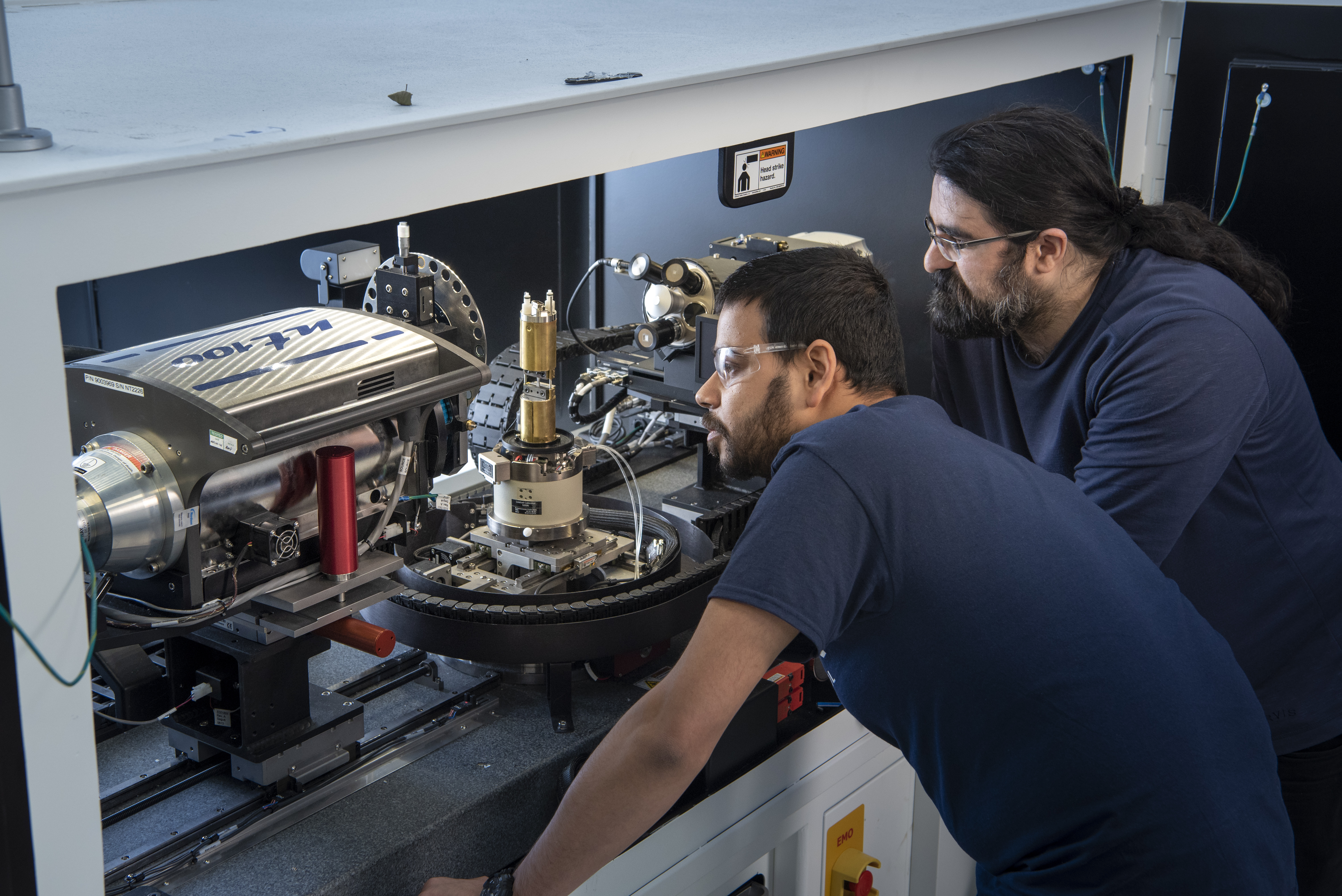

Sina Shahbazmohamadi wears his long black hair in a ponytail pulled back from his bearded face and smiles eagerly as he begins to talk about his work at the Innovation Partnership Building (IPB) at UConn Tech Park.

A mechanical engineer by training, Shahbazmohamadi does advanced research in 3D imaging at the Reverse Engineering, Fabrication, Inspection and Non-Destructive Analysis (REFINE) lab, one of eight industry-sponsored research centers in the IPB. He uses a suite of state-of-the-art electron, X-ray, and optical microscopes to explore, deconstruct, and reconstruct materials more than ten thousand times smaller than the head of a pin.

If you think about it, what we really want to do in any engineering system, whether it’s biological or mechanical, is see internal structures and understand what’s happening. — Sina Shahbazmohamadi

During his Ph.D. work, Shahbazmohamadi inspected the failure of turbine blades in gas turbine engines with 3D X-ray tomography, the same technology used in medical CT scans. This technology can capture structural attributes of a material without physically damaging it, allowing researchers to “see inside” down to a 700-nanometer resolution – about the size of a red blood cell.

“I became fascinated by the technique and quickly realized it could be used in a lot of other applications,” Shahbazmohamadi says. “So I began developing novel imaging methods that can be used to solve highly complex engineering questions.”

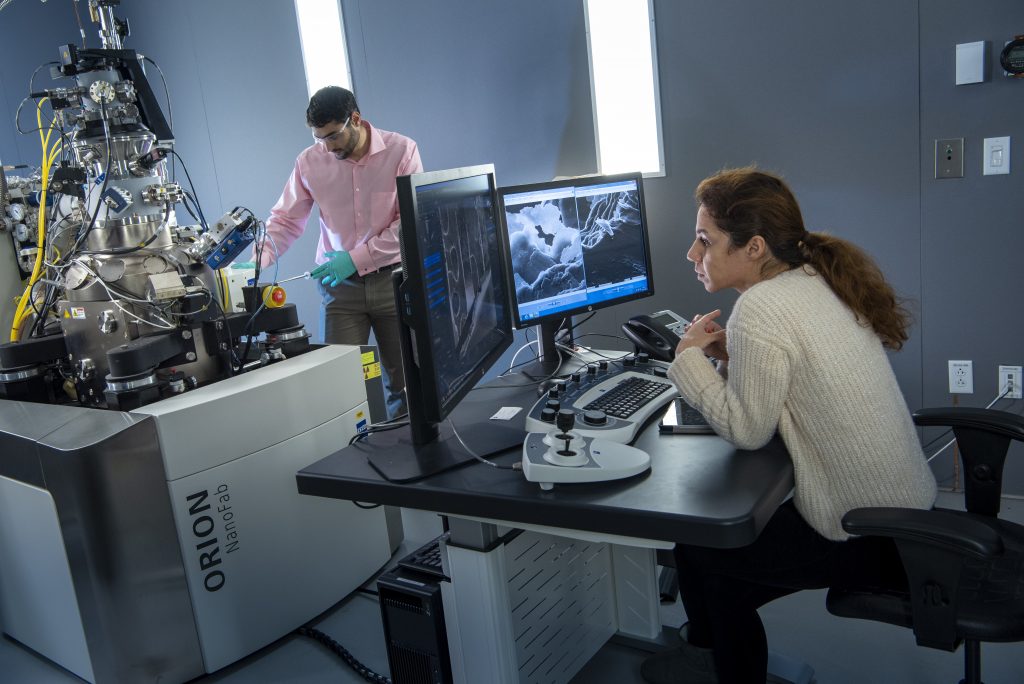

As Shahbazmohamadi began looking at increasingly smaller units, X-ray technology was no longer sufficient, so he started exploring applications of scanning electron microscopes (SEM) and scanning helium ion microscopes (HIM). More than one thousand times more powerful, this specialized equipment brings a complex challenge for Shahbazmohamadi to tackle: making the machines talk to each other.

Different microscopes allow us to view a system on increasingly smaller scales. However, when we move to a smaller unit, we lose the context that is essential to understanding its function. When we move a sample from a SEM to a HIM, we are able to zoom in from 10 nanometers all the way down to .3 nanometers. Information isn’t preserved from one instrument to another, so when we view the smaller field, we do not know where we are relative to the larger field of vision. By figuring out how to make his microscopes “communicate” with each other, Shahbazmohamadi will be able to move a sample from one microscope to the other, know precisely where he is, which all results in more precise data for his research.

Shahbazmohamadi’s work on materials characteristics at a microscopic scale has many potential applications that impact consumers, industry, and the military.

One project focuses on better ways to detect counterfeit nano and microelectronics.

“As electronics are getting smaller and smaller, we need more sophisticated equipment with higher and higher resolution to be able to see inside the components,” Shahbazmohamadi says.

His research is also making an impact on improving battery design for electric cars, cell phones, and laptops. In order to make better-performing products that are also lighter and less expensive, researchers need to be able to analyze and characterize the materials used to construct them.

Shahbazmohamadi, who is also an assistant professor in the Department of Biomedical Engineering, is keenly aware that the world of engineering is changing and research in one field is no longer isolated from applications in another. He is eager to apply technology across fields and is using imaging techniques to look at biological samples like human tumors and the brain.

“If you think about it,” Shahbazmohamadi says, “what we really want to do in any engineering system, whether it’s biological or mechanical, is see internal structures and understand what’s happening.”

Shahbazmohamadi is a firm believer in the tremendous power of human collaboration. When an engineer discovers or develops something, it usually only addresses one part of a problem. When researchers don’t or can’t share their findings, scientific advancement as a whole is stalled. So Shahbazmohamadi is working on a project that pools the findings and expertise of researchers from around the globe to combat a particularly complex, multi-faceted problem using a collective power greater than any computer.

The project provides a global community of scientists with online access to a 3D image of a microchip along with related imaging data, research, and shared results. Academic researchers, industrial partners and institutes have open access and can collectively contribute to finding possible defects that a single researcher might miss.

“People talk about using the computational power of high-performance computers, but, if you think about it, the greatest computational power is human beings,” Shahbazmohamadi says. “My one-year-old son can more easily detect a cat in our backyard, for instance, than the greatest computer in the world.”

Shahbazmohamadi sees this spirit of collaboration taking place every day at the IPB, which serves as a base camp for interdisciplinary collaboration as experts from different fields work only a few rooms away from one another.

“I can’t answer every question related to microelectronics. I need help from my materials science and electrical engineering colleagues,” Shahbazmohamadi says. “The IPB allows me ready access to their expertise, and is uniquely designed to house the state-of-the-art equipment that is required to make such interdisciplinary collaborations possible.”

The microscopes Shahbazmohamadi uses in his research and collaborations certainly are state-of-the-art. In fact, the IPB is one of only a few facilities in the country housing so many specialized microscopes under the same roof. This equipment is extremely sensitive and any number of acoustic, electromagnetic, or vibratory disturbances can impact the reliability of the data. The IPB building is designed to allow such instruments to function optimally.

Shahbazmohamadi has a uniquely collaborative relationship with ZEISS Microscopy, the manufacturer of the microscopes in the REFINE lab. ZEISS has shared not only their resources but their research challenges with Shahbazmohamadi’s lab.

“They invested in REFINE to take what we’re doing to the next level,” Shahbazmohamadi says. “Companies become part of us and we become part of them. It’s a win-win for both parties.”

Without this kind of connection to industry, Shahbazmohamadi says, the products and solutions developed by engineers may never make their way into the real world. He believes that this aspect of his work at REFINE has a critical impact on the numerous Ph.D. students and postdocs he works with at the IPB. He says being able to place a microchip in students’ hands and tell them the Air Force needs them to fix it, for example, has a profound effect on how students view their work.

“When someone starts their Ph.D., they already love science and engineering,” he says. “They want to do something great. Some of them want to change the world and it’s important to encourage them. At the end of the day, students like to know that what they’re doing is actually being used somewhere. It piques their interest and changes the level of education, plus the industry and the community benefit from the advances they’re making.”

Shahbazmohamadi’s work spans multiple research fields and utilizes the technology available at REFINE in exciting and inventive ways. He shows enthusiastic dedication to his students and his research. He is an advocate for science and collaboration. His work is moving science and industry forward by constantly looking at the world from newer and closer angles, from the outside in.

To learn more about the REFINE lab and the Innovation Partnership Building at UConn Tech Park, visit the Tech Park website.