The UConn Biodiesel Testing Laboratory, housed within the University’s Center for Environmental Science and Engineering (CESE), doesn’t make alternative fuels. But it does make them better.

“Fuels that are off specifications can wreak havoc in cars and heating oil systems, increasing corrosion and reducing the life of the engine,” says Richard Parnas, associate professor of chemical engineering. “Fuel quality has been a critical issue in the biodiesel industry.”

Biodiesel, says Parnas, is a renewable, “drop-in” replacement for regular petroleum diesel fuel. Unlike petroleum, which is made from fossil fuels, biodiesel is made from renewable sources, mainly oils from plants and algae. But, Parnas says, many people don’t realize that it can run as efficiently in engines as regular diesel.

“Biodiesel is capable of replacing a large fraction of the petroleum diesel fuel and heating oil that we use here in New England, in the United States and even worldwide,” he says.

Still in its infancy, the biofuels industry is touted by environmental groups for its sustainability. But according to Parnas, the budding industry also has considerable problems convincing the public that biodiesel is safe and effective, and with good reason: a 2006 estimate reported that about half the biodiesel produced in the U.S. was sub-standard.

“When biofuels cause problems, that give a black eye to the industry,” says Parnas. “It reduces people’s confidence in the fuels and reduces business opportunities for the companies that are trying to make this industry work.”

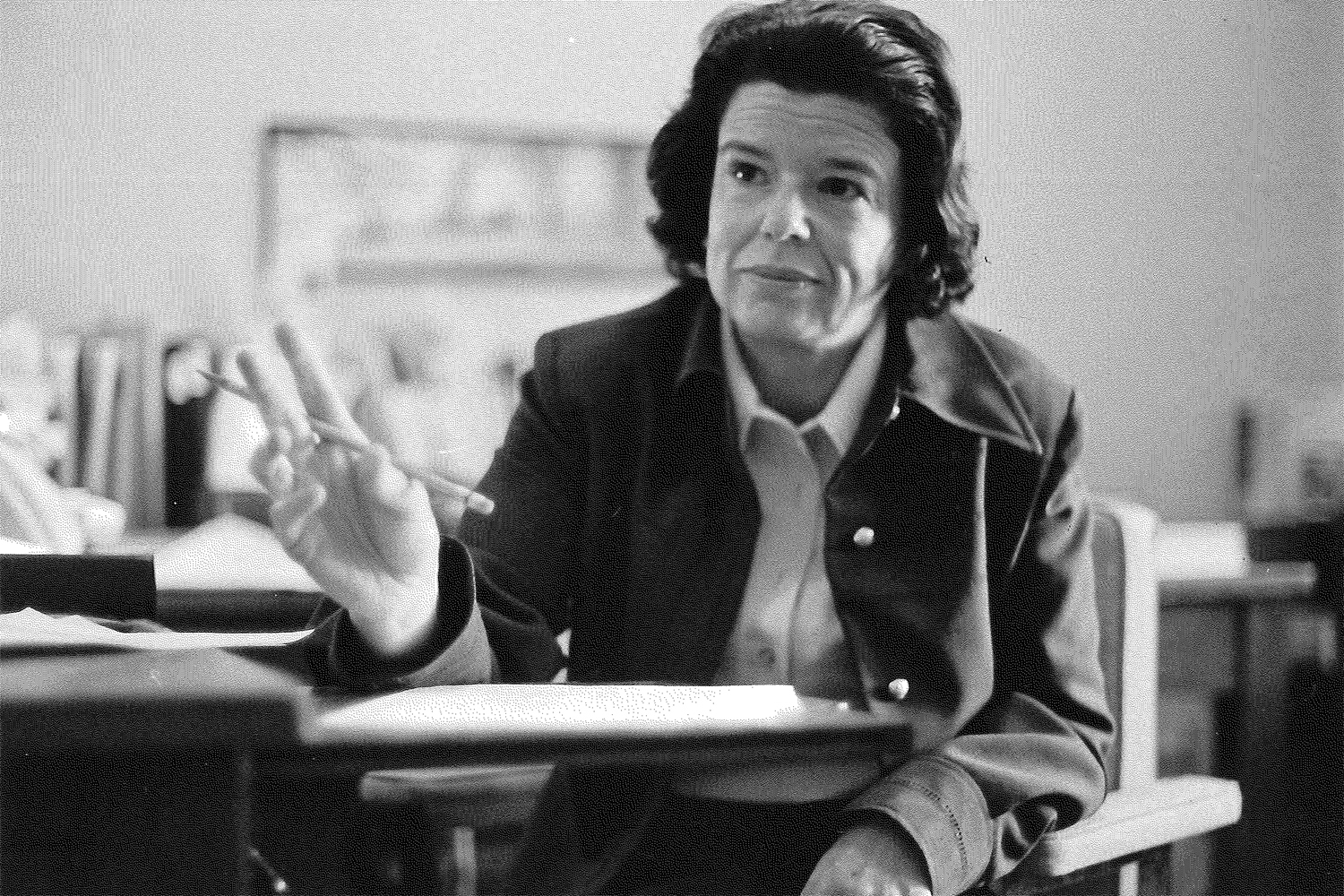

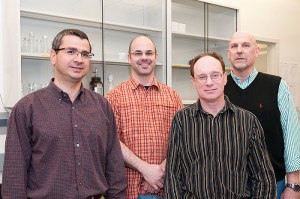

In 2009, the University received a $600,000 grant from the state of Connecticut to help establish the Biodiesel Testing Laboratory. The laboratory held its grand opening today with an open house and invited symposium on biodiesel. Attendees received an overview of the lab’s mission and a tour of the facility. Speakers included the Connecticut House Majority Speaker Denise Merrill; Suman Singha, UConn’s vice president for research and graduate education; and members of the lab’s founding team.

Anthony Provatas, a research scientist at CESE who performs the testing, receives two to three samples per week of biodiesel from around the state and the country, and performs 14 different tests to ensure the fuel meets standards set by the American Society for Testing and Materials and the National Biodiesel Board. The tests examine physical and chemical properties of the fuel, such as its density and acidity.

If a sample passes the tests, then the company can sell that batch of biodiesel. But if the sample doesn’t pass, says CESE laboratory director Christopher Perkins, the process doesn’t stop there.

“One of the reasons our clients are so loyal is that we provide extra service in-house to help them troubleshoot their processes,” says Perkins. “We work with clients to provide a forensics approach to what their problems are. We try to help them get beyond the tests they failed, so they can meet specifications and pass.”

Another reason many of the lab’s clients are loyal is the price. The going commercial rate for testing a quart of biodiesel is around $1,000, which can cost a small company that produces about a million gallons of biodiesel per year upwards of $350,000 annually. But Connecticut companies can get this same testing done at a discount of 75 to 80 percent.

This price cut creates an incentive for people to set up their biofuels companies in the state, which CESE director Mike Willig says will generate enormous potential for jobs and economic growth.

“The founders of this laboratory had a vision that UConn could help the state stimulate business and the production of jobs, and introduce an energy form that would be both efficient and environmentally friendly,” he says.

Willig adds that the lab doesn’t intend to supplant the more expensive testing companies. On the contrary, he says, their lab aims to jump-start the biofuels business.

“We hope to catalyze the industry, and once it’s on firm footing, we expect that the private sector will take on this responsibility,” he says. “We see ourselves phasing out of the testing business as time goes on.”

Most importantly, Willig says, UConn hopes to create a culture of trust for the new alternative fuels.

“We’re assuring the public that there are high standards associated with the production of biodiesel, and that it is as reliable and as useful as any fuel,” he says. “This is a quality fuel that the public can use in their homes or cars without worries.”